Add to Cart

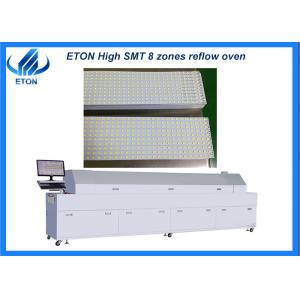

8 zones 1200kg SMT line production equipment PID control + SSR drive reflow oven

Features

Technical Parameter

| Product model | ET-R8 | |

| Heating system | NO. of heating zone | Upper 8 hot air heating, lower 8 hot air heating |

| Length of heating zone | 3000mm | |

| heating method | Full hot air | |

| Delivery system | PCB maximum width | 450mm mesh belt, no lead rail |

| Transport direction | left-right,right to left(option) | |

| Conveyor belt height | Mesh belt 880±20mm | |

| Delivery method | Mesh belt drive + rail (optional) | |

| Conveyor speed | 0-2000mm/min | |

Control System | power | 380V 50/60Hz Three-phase five-wire AC:380V 50Hz |

| Starting power | 28KW | |

| Working power | 7KW | |

| Heating time | Around 15 mins | |

| Temperature control range | Room temperature~350℃ | |

| Temperature control method | PID control + SSR drive | |

| Temperature control accuracy | ±1℃ | |

| Abnormal alarm | Abnormal temperature alarm | |

| Machine system | Machine dimensions(L*W*H) | 5000mm*1000mm*1500mm |

| Machine weight | 1200kg | |

Reflow soldering technology is not new in the field of electronic manufacturing. The components on various boards used in our computers are soldered to the circuit board through this process. There is a heating circuit inside this device, which uses air or nitrogen After heating to a high enough temperature, it is blown to the circuit board on which the components have been pasted, so that the solder on both sides of the components melts and bonds with the main board. The advantage of this process is that the temperature is easy to control, oxidation can be avoided during the welding process, and the manufacturing cost is easier to control.

Machine main part

Certificates

As an experienced manufacturer in SMT machine, we obtained a number of intellectual property technologies, including 9 invention patents, 112 practical patents, 12 software copyrights, with our won R&D department for production and inspection. And also earned the oversea certificates as CE, CCC, SIRA,

etc.

Packages

Step 1: Packing in film package to prevent dust and water to the machine

Step 2: Packing in foam cotton to protect the outside of the machine

Step 3: Packing in vacuum package to keep dry of the machine during transportation

Step 4: Transportation by truck to specified port

FAQ

Q. How many hours does the machine can operate per day?

A.Machine can work whole day. But for longer using life, we suggest you to have 1 hour or 2 hours off per day.

Q. Can you accept CIF as the quoted price?

A. We only accept EXW as the quoted price for it is convenient and lower cost for both sides.

Q. Can I go and see if you have sold the equipment to India?

A. Yes, we have sold our machine in India, but for the fact we can't decide it for my customer, but I will try to contact my customer. Hope you can understand, because no one wants their competitors to visit their manufacturing site.

Q. How many products can your machine make per day?

A. The capacity of our machine is according to the real products, and the number of components on your PCB board that is important factor to figure out the actual speed of our machine with your products.

Contact me:

Whatsapp/Wechat: +8613632769526

Email: Noah@eton-mounter.com