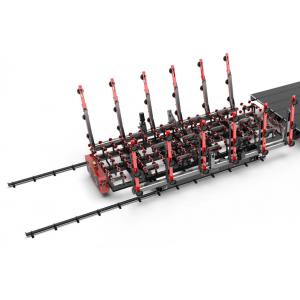

Automatic Vertical Two Layers EVA Laminated Glass Machine With One Working Station

Add to Cart

CNC Automatic Vertical Two Layers EVA Laminated Glass Machine With One Working Station

1.Feature

This machine can produce the traditional laminated glass, also can make different laminated glass with different material, such as silk, cloth, metallic braid and so on,in the middle between the two glasses, use EVA film. If you add the material differently, the use effect is also different. These products also have many kinds of functions like sound-insulated, the heat insulation, the explosion-proof, bullet proof and so on.,have been widely used and well in demand for home, bank, hostipal, store, show-room, Image CIS and so on.This machine can produce all kinds of laminated glass, such as safety glass, bullet-proof glass, metal wire-reinforced glass, PDLC smart glass, decoration marble glass, decoration glass, double-decked steel marble glass, color silk glass, color portrait glass, and so on.

This Automatic Glass Cutting Line has been comprehensively upgraded by means of introduction of European leading technology, world newest tech and process to eliminate the insufficient performances, incomplete functions and unstable operation from domestic glass loader, moreover,through the precise racks, slide-rails, servo motors and pneumatic elements, it achieves the long-term stable accuracy and fast running with the newest American Galil control system, it features even faster operation, higher safety, higher efficiency, more stability and better accuracy: with the photoelectric positioning, it facilitates the simple and precise operation and prominent labor saving.

2.Equipment element

1) two beds

2)Air Storage tank

3) Silicone bag

4) Vacuum pump

5)Heaters:

6)Special Cotton for Keeping Temperature

7)Famous Electricity parts with long life

8) Automatic Program alarm system(to warn you after one process finish)

9)automatic lifter

3.Product main use

Construction of inner wall glass, bulletproof glass, high-level office block, CIS enterprise image, furniture, church, dance floor, villa, valance curtain, wall windowpane, tabletop, craft glass and so on.

4. Advantage

Does not require extensive financial investments, the security results is high, effective and reliable. Short production cycle, occupies minimum size of factory area.

5.Specifications

· Overall dimension: 3100*2350*1250mm

· Power: 380V 50HZ/ 220V 60HZ

· Total power: 21kw

· Amper: 100 A

· Vaccum time: 5 minutes

· Heating time in Low temperature: 5 minutes

· Heating time in high temperature: 25 minutes

· Keeping temperature time: 35 minutes

· Cooling time: 15 min

· Heating temperature: 110-150 degree

· Working dimension; 2500*1900mm

· Layer: can up to 5 layers

· Station:Can become 2 Working Station

· Weight: 1500kg

We are quite flexible to satisfy every customer’s request.

Our Goal

Jinan Lijiang Glass Machine provides full set services and high-quality but low-price products.We are always looking for long term cooperaion, not one time deal.

Pre-sale

Jinan Lijiang Glass provides 24 hours high-quality service.When clients contact Jinan Lijiang Glass and ask for products, Jinan Lijiang Glass answers at once, except our clerks sleep, which condition we answer within 10hours. Jinan Lijiang Glass understand how important it is for the customers to choose a suitable machine ,we are ready to come up with a best solution for customers.

On-sale

For all you requests,we will supply the best solution to you as soon as possible.If you have any inquiry or problems,please contact us with E-mail, skype, alibaba website platform, whatsapp, phone calling, etc. Jinan Lijiang Glass welcome customers to visit the factory, we will pick you up from airport or train station. Jinan Lijiang Glass location is convenient to welcome clients because of next to train station.

After-sale service

When customers buy the glass processing machine, Jinan Lijiang Glass promises that the machine will be delivered in 20-25 days after deposit. Jinan Lijiang Glass arranges commodity’s packages suitable for shipment of sea. Jinan Lijiang Glass provides English instruction about manual guide and video technical support. Any problems please let we know, and we will give detailed supports and advice. Jinan Lijiang Glass promises worry-free repair of one whole year after installation, the original fault parts damaged, be free of anycharges.When the serious breakdown and big fault happens, Jinan Lijiang Glass has engineers and they can fly to there to solve it.

Technical Parameter