Add to Cart

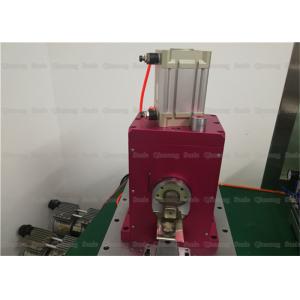

Special Customized Reticulation for Ultrasonic Metal Welding Horn

with Imported Steel Mold

Description:

Ultrasound is widely used in medicine, military, industrial and

other industries due to its good directionality and strong

penetrating power. Ultrasonic metal spot welding machine is the

heat generated by the vibration friction of tens of thousands of

times per second of ultrasonic wave. The energy of ultrasonic

vibration is converted into friction energy and transmitted to the

metal surface, and then the external pressure is used to fuse the

molecular layer of the workpiece contact surface.

Specifications:

| Item No | QR-D2020A | QR-D2030A | QR-D2050A |

| Power | 2000W | 3000W | 5000W |

| Air Pressure | 0.05-0.9MPa | 0.05-0.9MPa | 0.05-0.9MPa |

| Frequency | 20KHZ | 20KHZ | 20KHZ |

| Voltage | 220V | 220V | 380V |

| Weight of horn | 55KG | 60KG | 88KG |

| Dimension of Horn | 550*280*380mm | 550*280*430mm | 550*380*660mm |

| Generator Size | 540*380*150mm | 540*380*150mm | 540*380*150mm |

Applicable Products:

1) Nickel-metal hydride battery Nickel-metal hydride battery nickel mesh and nickel sheet inter-melting and nickel sheet inter-melting.

2) Lithium battery, polymer battery copper foil and nickel sheet are mutually melted, and aluminum foil and aluminum sheet are mutually melted.

3), the wires are mutually melted, and they are entangled into one and a plurality of mutually melted.

4), the wire and various electronic components, contacts, connectors inter-melting.

5), the mutual melting of large-scale heat sinks, heat exchange fins and honeycomb hearts of various household appliances and automotive products.

6), electromagnetic switch, no fuse switch and other large current contacts, mutual melting of dissimilar metal pieces.

7) The sealing and cutting of the metal pipe can be water and airtight.

How does an ultrasonic welder work?

The principle of ultrasonic welding is to convert 50/60 Hz power

frequency to 20 kHz or more by ultrasonic generator. The converted

high frequency electrical energy is again converted by the

transducer into mechanical vibration of the same frequency, and

then the mechanical motion is transmitted to the welding head

through a set of amplitude varying amplitude modulators. The

welding head transfers the vibration energy to the joint of the

workpiece to be welded, in which the vibration energy is converted

into mechanical energy and thermal energy by friction, so that the

workpiece to be processed is welded. Ultrasonic waves can be used

not only to weld hard thermoplastics, but also to weld metals.

Ultrasonic welding of plastics generally uses the way the welding

head vibrates perpendicular to the workpiece. For some thin plastic

parts, the direction of vibration of the welding head can be

parallel to the workpiece. When ultrasonic welding of metal, the

direction of vibration of the welding head is parallel to the

workpiece.

Since vibration propagates in metal with various vibration modes:

longitudinal vibration, radial vibration, bending vibration, and

torsional vibration, it is possible to comprehensively analyze

which vibration mode is used according to the material to be

welded, and pressurize based on the vibration mode. The design of

the mechanism and the frame.

The main components of a set of ultrasonic welding systems include

ultrasonic generators, transducers/amplifiers/welding heads, molds

and frames. The main functions of the frame are fixed and stroke

pressurization mechanisms.

Special Customized Reticulation for Ultrasonic Metal Welding Horn

with Imported Steel Mold