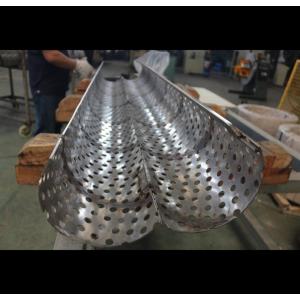

Perforated Muffler Exhaust Pipe Panels Filters Strainers For Insulation

Add to Cart

Perforated Muffler Exhaust Pipe Panels Filters Strainers For Insulation

Process Details

1. Choose the material.

2. Choose material sheet gauge.

Sheet metal thickness is measured by the gauge. The larger the gauge, the thinner the material.

3. Choose/design a perforation pattern.

4. Perforate the sheet metal via bending, welding, punching, cutting, etc.

Sheet metals perforation is performed using two likely methods, depending on the repetitiveness, complexity and general design of the hole patterns. Simple perforations may be fabricated using a standard punching press, which is a large press containing whatever hole pattern the manufacturer requires. To achieve the desired perforation, sheet metal is simply fed through the press, which punches it. For more complex perforation designs, like decorative panels that use many non-repetitive shapes, manufacturers use a sectional XY axis punching press. This press is usually CNC controlled, thus ensuring precision and accuracy.

5. Perform any finishing processes.

Examples include: grinding, brushing, rounding, degreasing and surface polishing.

Product Name | Stainless steel perforated filter elements | ||

Hole shape | Round hole, square hole, elliptical hole, long square hole,

multilateral hole, rhombus hole, star hole, ten flower hole, plum blossom hole, louver

hole, shallow drawing hole,or customized | ||

Feature | 1.Good filtration performance to the 2--200um. 2.High temperature resistance, and suddenly-changing temperature resistance. 3.Resistant to corrosion, suitable for many kinds of acid alkali and other corrosive medium especially suitable for sour gas filtration. 4.High strength and good toughness, suitable for high pressure environment. 5.Weldable, facilitate handling. 6.Large flow per unit area 7.Can be used repeatedly after cleaning | ||