Product Details

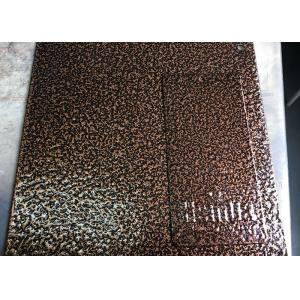

Electrostatic Spray Powder Coating UV Resistance Rough Surface Good

Heat Flow

Powder Coating Colours

The list of powder coating colours is vast. Generally we cover all

the standard colours. RAL is a colour reference system that was

invented in 1927 by Reichsausschuss fur Lieferbedingungen in

Germany. While there is a wide choice of standard colours we can

also colour match any current corporate colours and produce custom

powders.

For further information on powder coating colours please contact

us.

Products series

- Available in standard curing and lower temperature curing

- Available in multi-colors, different gloss level such as high gloss

( above 90°), flat gloss( 70-80°), semi gloss ( 10-60°), matt(

below 10°), particular color and gloss is made according to

customers requirements.

- Available in various kinds of art textures, such as sandy, wrinkle,

lanose grain, hammer tone, metallic effect etc.

Physical property

Specific gravity: 1.11.8g/cm3 (varied with different color and

gloss)

Particle size: average 10~38um, proportion 10~84um > 90%, it can

be adj

Other product

- Our Powder finishes are available in a vast range of colors and

finishes.

- Including metallic effect,chrome effect,wood grain,Candy Color Powder ,MDF

powder

- and other special effect,making them ideal for indoor decoration of steel furniture,

- and outdoor metal products such as agricultural machinery, auto

parts

product detail

| Type | Epoxy Powder Coating; Polyester Powder Coating; Epoxy-Polyester Powder Coating |

| Color | Ral&Pantone color |

| Surface Finish | Superior gloss and color retention |

| Particle Size | Average 32-42μm |

| Specific Gravity | 1.2-1.7g per cubic meter |

| Coverage | 8-10 square meters per Kg at 30-90 μm film thickness |

| Film thickness | Not less than 100μm |

Instruction

| Application Voltage | 60-90 KV |

| Gun to Component Distance | 15-30CM |

| Curing Temperature | 180-200℃,10 min-15 min |

Storage stability

| Store in ventilated, dry, clean room, temperature < 25℃ | Relative humidity 50-65% |

| Away from direct sunlight, fire, heat | For best performance, use within 6 months |

Product process

- Powder coatings are based on Resin,Pigments,Curing

Agents,Additives.

- Resin(including Epoxy, polyester, hybrid)giving the basic performance to

the coating.

- Pigments, Providing the colour and effects, such as metallic or hammer.

- Curing Agents, reacts with the resin to form a continuous protective film.

- Additives, can be used to promote variations in the performance or surface

effects.

Company Profile

Hsinda——Top 1 Powder Factory in Southwest China

We are a team that is good at meeting change and being innovative.

We focus on what we should do – “customer first”, insist on innovation, integrity, passion, and dedicated

teamwork.

At Hsinda, we follow and enforce best practices to deliver high

quality products and services. Hsinda has the ability to accept any

customization, all the color on RAL&PANTONE card can be made.

Besides, color can be customized for your sample or requests.

Hsinda has been certified SGS and accorded with EU

standard(ROHS2.0).

Hsinda has its own R&D center and is committed to developing

new products to better meet your needs. We are a dedicated team and your true partner, if you want to know

more about coating solutions and technologies support, welcome to

join us and enjoy the colorful world.

Our teams

Our factory

Hsinda in Russia Coating Exhibition

Hsinda in Kenya Coating Exhibition

Hsinda in Vietnam Coating Exhibition

Customer visit our factory

VISION

Beyond Your Imaginations

MISSION

Global Technology Enterprise

Team Spirit

Hsinda not only emphasis on the product quality, but also put a

high view on personal quality and team spirit of all staffs. We are

to“ our gratification derives from customer satisfaction" for the

purpose and remain a state ofenthusiastic and optimistic. Our

company not merely often organized various trainings but carried

out outdoor activitiesfor improving comprehensive ability of all

staffs.