Automated Operation 12.5% Sodium Hypochlorite Generator for Chlor-alkali Plant

Add to Cart

Automated Operation 12.5% Sodium Hypochlorite Generator for Chlor-alkali Plant

Brief Introduction:

Considered Inherently Safe Technology (IST), Klorigen™ provides a safe and efficient alternative to traditional pressurized chlorine gas offers a lower cost option to commercial bulk-delivered sodium hypochlorite. This technology allows users to generate on-demand at the point of use, eliminating any possibility of hazardous gas release.

Klorigen™ generators uniquely combine brine electrolysis with

advanced membrane technology to deliver chlorine gas under a vacuum

as well as co-product sodium hydroxide (caustic soda) available for

pH elevation. Alternatively, the chlorine and sodium hydroxide

products can be combined within the process to produce sodium

hypochlorite at concentrations up to 15% (150 g/L).

Features and benefits:

1. Chlorine gas safely generated on demand at ambient (1 bar) pressure

2. Capable of simultaneously producing chlorine gas, sodium hydroxide and high strength sodium hypochlorite (up to 15%)

3. Proven chlor-alkali technology uniquely modified for on-site applications

4. Easily adjustable output (systems have a 10:1 turndown ratio)

5. Minimal operator involvement (less than one hour per day)

6. Modular design facilitates future expansion without significant increase in footprint

7. Warranted up to five full years of operation

8. Quiet operation - few rotating components

9. Automated sensors and shutdowns

10. Easily fitted with or adapted to SCADA control systems

11. Cost competitive with most alternative treatment methods

Applications

Traditionally, water utilities have used chlorine gas as the

disinfectant of choice in their

treatment plants. However, as the global specter of terrorism grows

and public safety

issues continue to rise in prominence, concerns have been raised as

to the future of this

practice.

Although some progressive public utilities are evaluating

alternative technologies to

pressurized chlorine gas, chlorine remains the most effective

broadband disinfectant. In

response to this preference, Klorigen™ on-site chlorine gas

generators can facilitate the

continuation of current disinfection methods while promoting safe

practices through the

use of chlorine gas at ambient pressure.

Alternatively, water disinfection may be safely and effectively

accomplished using

Klorigen™ on-site generation of high strength sodium hypochlorite

solution. Storage of

12.5% concentration requires less than one-fifteenth of that needed

for "low-strength"

(i.e. less than 0.8%) generated sodium hypochlorite.

Specifications

| Maximum Daily Production Rates | K-4 | K-8 | K-16 |

| Chlorine gas | 565 kg/day | 1125 kg/day | 2250 kg/day |

| 15% sodium hydroxide | 3650 L/day | 7300 L/day | 14600 L/day |

| 12.5% sodium hypochlorite | 4750 L/day | 9500 L/day | 19000 L/day |

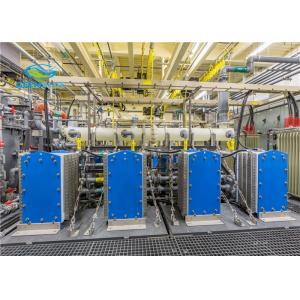

System flow chart