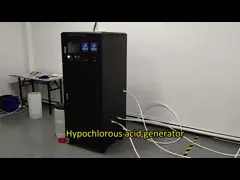

6kg/h Sodium Hypochlorite Generator 0.8% Concentration For Disinfection

Add to Cart

6 KG/H On Site Sodium Hypochlorite Generation With 0.8 % Concentration For Disinfection

Sodium hypochlorite

GEEMBLUE series Electro-chlorination Generator produce the disinfectant sodium hypochlorite from sea water or salt water (Brine) on your own site. Sodium hypochlorite solution, commonly known as bleach is frequently used as disinfectant.

Reaction Principle

Seawater or refined salt is mixed with softened water in the

saturator to from saturated brine. It is diluted to 3% by softened

water and injected into the electrolyzer. The solution is then

electrolyzed with direct current (DC power).

This results in chlorine (Cl2) gas being produced at the anode,

while sodium hydroxide (NaOH) and hydrogen (H2) gas is produced at

the cathode. These two substances react with each other to form

sodium hypochlorite solution.

The electrode reaction and solution reactions is

Electrode reaction:

at the anode: 2Cl- - 2e → Cl2;

at the cathode: 2H+ + 2e → H2;

Solution reaction:

2NaOH + Cl2 → NaCl + NaClO + H2O

Overall reaction as follow:

NaCl + H2O + DC →NaClO + H2↑

System Flow Chart

Product components

Electrolytic cell

Geemblue series unique electrolytic cell design optimizes salt and

power consumption while providing easy access to the cell

components for maintenance. A clear organic glass cell body allows

for visual inspection, and the improved end-connection cap design

minimizes the potential for leaks.

Electrode

TA1 pure titanium electrode, with ruthenium &iridium oxide coating which ensure over 5 years coating life, over 18 years base material, reduce the chlorine evolution potential and electricity consumption.

Brine Proportioning Unit

To proportioning saturated brine with softened water into 2.5~3% diluted brine.

Siemens PLC Smart Control Center

| Auto Dissolving & Proportioning | Automatic dissolving salt into saturated brine and proportioning into 2.5~3% |

| Auto Electrolysis | Automatic control electrolysis and produce accurate amount and concentration of sodium hypochlorite solution |

| Auto control storage | The Start/off of system can be controlled by PLC according to the solution level in storage tank |

| Auto dosing | Auto adjust dosing pump accurately according to the water flow and value of residual chlorine meter |

| Real-time Monitoring | All running data(current, voltage, temperature, conductivity, solution level, hydrogen concentration) can be real-time monitored from LCD touch screen |

Electrolytic cell

Electrode

Siemens PLC Smart Control Center