Add to Cart

5 Ton/Hour Animal waste organic fertilizer making pellet production line

Product Description

Production of organic fertilizer

The organic solid waste resource is utilized by building an organic fertilizer plant. The raw materials can be chicken, duck, pig, cattle, sheep manure, biogas residue, mushroom residue, potato residue and crushed crop straw. Through biological fermentation technology and scientific processing (bio-fermentation, high-temperature sterilization, deodorization, drying, crushing, etc.), they're turned into environmentally-friendly and high-efficiency organic fertilizer with good quality and stable effect. Thus, efficient and resourceful utilization of organic waste is realized and it also achieves a win-win situation for both economic and environmental benefits.

Features of Animal waste organic fertilizer making pellet

production line

1. The line takes animal manure and agricultural waste as its main

material, not only turns the waste into valuable things, but also

protects

the environment.

2. The whole fertilizer production process is centralized

controlled, so this series of fertilizer machines are highly

automatic and easy to

operate.

3. Both batching system and packing system are controlled by the

computer, thus ensuring the precision of material batching and

fertilizer

packing.

4. High-quality, stable performance, compact process layout,

advanced technology, and convenient maintenance.

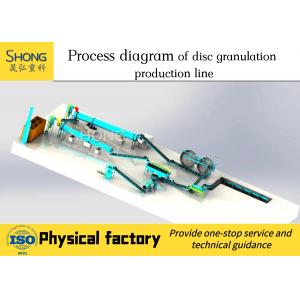

The process of Animal waste organic fertilizer making pellet

production line

Bio-organic Fertilizer Production plant is a complete set of

equipment from raw materials collection to the organic fertilizer

packing.

The whole organic fertilizer production line include the following

machines:Raw material Fermentation→ fertilizer crushing machine→

fertilizer mixing machine → rotary drum granulator → rotary drum

drying machine → rotary drum cooling machine → rotary drum coating

machine → rotary screening machine → packaging machine → spraying

granulating system→ belt conveyor → and other accessories.

1.Organic materials fermentation process plays the preliminary but

indispensable role in the whole production line. Two main types of

compost turner are widely used to turn and mix the compost and

accelerate the fermentation speed: Self-propelled compost turner

and hydraulic compostturner.

2.Crushing Process: The compost lump materials should be ground

before the granulating process. But we can leave out crushing

process when the compost material is fine enough. Vertical chain

crusher and double-shaft horizontal crusher, two types of crushing

machine can be used to crush lump compost fertilizer raw materials.

3.Mixing Process, two types of mixing machine are applied to mix

raw materials in the fertilizer production line: horizontal mixer

and vertical mixer.

4.Drying process. When granulating, the moisture of fertilizer raw

materials should be less than 25%, so we should dry the raw

materials if the moisture is more than 25%. Rotary drum drying

machine is mainly used for drying the fertilizer with a certain

degree of humidity and particle size.

5.Granulator Process. Granulating process is the core part in this

production line, so we choose the suitable model of fertilizer

granulator according to customers detailed requirements.

Optional granulator equipment: organic fertilizer combination

granulator, organic fertilizer special granulator, pair roll

extrusion granulator, disc granulator, flat film granulator, bio

organic fertilizer spherical granulator, Drum granulator, round

tossing machine, etc.; Typical application materials: chicken

manure, cow dung, kaolin, etc.

Organic manure, animal manure, manure, manure, composted manure,

green manure, sea manure, cake manure, peat, microbes and other

organic manure fermented fertilizer granules, the particles are

irregular spherical. The granulation rate of Huaqiang Organic

Fertilizer Granulator is over 95%, which is suitable for a variety

of different formulas. The compressive strength of organic

fertilizer is higher than that of disc and drum granulator, and the

particle size is uniform. It is suitable for direct granulation

after fermentation, saving drying process and reducing

manufacturing cost.

6.Rotary Drum Cooling Machine is used for cooling fertilizer to

make fertilizer particles stronger.

7.Screening process:Rotary drum screening machine is used to

separate the granules from the large particles which need to be

returned for the second crushing and granulating. Rotary drum

coating machine is used to coat the fertilizer and prevent the

fertilizer from sticking together.

8.The last process is packaging process. Fertilizer packaging

machine can package bags quantitatively and automatically.Including

electronic quantitative packaging scale, silo, automatic sewing

machine, etc. It also need some auxiliary equipment for connection

such as belt conveyor, bucket elevator, etc.

Function of Organic Fertilizer

1. It can improve and fertilize soil. The organic fertilizer

contains mainly organic matter, so its application will increase

the organic matter in the soil, loose soil, and also fertilizes the

soil.

2. It can increase crop yield and improve crop quality by providing

crops with effective nutrients such as nitrogen, phosphorus,

potassium, amino acids, etc., meanwhile, it can also promote soil

microbial activities.

3. It can improve fertilizer utilization, as organic fertilizer and

fertilizer will promote each other, which is conducive to crop

absorption.

4. It can increase the soil gap, make the soil loose, so as to

promote the development of roots, and improve the drought tolerance

of crops.

5. The rational use of organic fertilizer can reduce environmental

pollution, protect the environment and ecological balance.