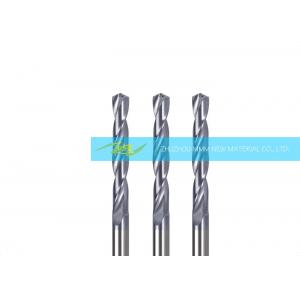

5D Internal Cooling Carbide Drill Bits For Hardened Steel / Hss Drill Bits

Brand Name:MMM

Certification:ISO 9001

Model Number:D3.0-D20.0

Minimum Order Quantity:5 PCS

Delivery Time:5-15 Days

Payment Terms:L/C, T/T

Contact Now

Add to Cart

Active Member

Location:

Zhuzhou Hunan China

Address:

Room 421, Zhishang Science and Technology Building, 1986 Taishan West Road, Tianyuan District, Zhuzhou, Hunan, China

Supplier`s last login times:

within 30 hours

Product Details

Company Profile

Product Details

Solid Carbide Drills for Stainless Steel Drilling with 5D Internal Cooling

The First Choice for Stainless Steel Drilling.

Feature Advantage:

- D3.0-D20.0 diameter

- The length includes 3D and 5D.

- Each model has two types: internal cooling and external cooling.

- The first choice for mild steel and stainless steel drilling.

- The sharp cutting edge avoids the formation of built-up edge and is suitable for high performance drilling.

- The optimized drill tip structure enhances the strength of the chisel and inner edges, makes the cutting lighter and the chip breaking is better.

- Nano-TiAlN coating for excellent wear and high temperature resistance.

- The unique groove structure has large effective chip space, smooth chip removal and stable drilling.

Technical Information:

- Typical application of integral alloy drill bits:

- Small diameter hole

- Tight or precision tolerance hole

- The hole shorter than a deep hole

- Chip clogging can cause the drill bit to move radially and affect hole quality, bit life and reliability.

- Chip formation and chip evacuation are important issues in drilling. It depends on the workpiece material, blade geometry selection, coolant pressure, capacity, and cutting parameters.

- The drill bit is mounted on the shank chuck and its circumferential runout must be less than 0.02 mm.

Recommended Cutting Parameters:

- When using this series of tools for the first time, the cutting is performed according to the recommended cutting speed of 90% or the feed rate of 85%. When the cutting condition is stable, the cutting speed and the feed are increased one by one.

- Cutting parameters are recommended for water soluble cutting fluids.

- Use a defect-free, clean chuck when installing the drill and control the drill runout to within 0.02 mm.

- The recommended cutting parameters are for applications where the hole depth is below 5D.

- The recommended cutting parameters are externally cooled drills, which can be increased by 10%-15% depending on the situation.

5D Internal Cooling Carbide Drill Bits For Hardened Steel / Hss Drill Bits

Inquiry Cart

0