Add to Cart

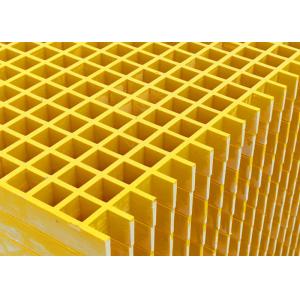

35*35*35 Fiberglass Grating Panels , Pultruded Fiberglass Grating

1. Slip-resistant

Fiberglass grating has a concave top surface for slip resistance

after it is extracted from the mold. Should a grit surface be

specified, the fiberglass grating would be either bonded to the top

of the completed grating as a secondary operation or embedded to

the top of grating before heating, both providing superior slip

resistance. Diamond cover top or gritted cover top are also

available upon request.

2. Life span

More than 20 years of Life is guaranteed for PowerGrate gratings.

3. Low maintenance

Install it and forget about it. Fiberglass grating is easy to

clean, its open meshes permitting debris to fall through grating

and preventing hazardous buildup on walking surface.

4. Safety

NON-CONDUCTIVE property makes fiberglass grating ideally suitable

in electrically hazardous locations acting as an insulator.

NON-MAGNETIC property allows fiberglass grating to be used in sensitive installations where the inherent magnetic properties of metal grating will prove dangerous.

5. Comprehensive economic efficiency

The cost of fiberglass grating is about 1.4-1.8 times that of steel

grating, installation cost is about 20-40% that of steel grating,

and maintenance cost is about zero. But steel gratings must be

maintained every year, and the accumulated cost will be a very high

sum. Therefore, the cost of

PowerGrate grating is a little higher than that of steel grating,

but the comprehensive economic efficiency, plus other advantages,

is much higher than that of steel grating.

Mesh size(mm) | Thickness(mm) | Whole panel size(mm) |

| 38×38 | 25 | 1400×4200, 1220×3660 |

| 30 | 1220×3660 | |

| 38 | 1220×3660, 1220×4000, 1525×3660 | |

| 65 | 1220×3660, 1032×2020 | |

| 50×50 | 50 | 1220×3660 |

| 25×100 | 25 | 1000×4000 |

| 40×100 | 65 | 1015×1295 |

| 38×152 | 38 | 1220×3660 |

| 19×19/38×38 | 30 | 1220×3660 |

| 13×13/40×40 | 40 | 1010×4050 |

| 25×25/50×50 | 30 | 1000×4000 |

| Remark | Customized size available based on large order | |