Add to Cart

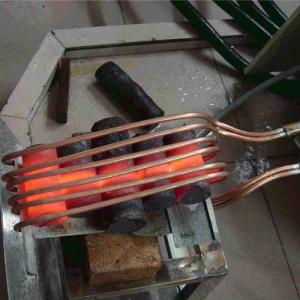

1. Brief introduction of steel bar / steel plate induction heating machine:

High-frequency induction heating equipment, also known as

high-frequency heating machine, high-frequency induction heating

machine, called "high-frequency induction heating power supply" or

"high-frequency power supply" in China, also called high-frequency

induction heating machine in Guangdong and Taiwan, according to the

workpiece Different from the application field, it is also called

medium frequency induction heating equipment and super audio

frequency induction heating equipment.

It is mainly used for inductive heating of metals (non-contact);

the inverter elements used generally use thyristors, vacuum tubes,

etc.; the technology of using thyristors as inverter elements is

very mature, and the power can be To hundreds of KW or more, but

the frequency is generally below 10KHZ.

When the vacuum tube is used as the inverter element, the frequency

and power can be very high, but the power consumption is too large

and it is easy to be damaged. IGBT and MOS tube are a new component

in the high frequency industry, which can replace thyristor and

vacuum tube respectively.

2. Feature of IGBT steel bar / steel plate induction heating machine:

1. It adopts the most advanced IGBT frequency conversion control

technologies to ensure the high efficiency and maximum output

power.

2. It has the constant current and power control function, which

can significantly optimize metal heating process, realize the high

efficient and fast heating and bring into play the superior

performance of the products.

3. It has the function of three-stage time setting represented by

heating-heat preservation-cooling. Furthermore, the power for

heating and heat preservation is available for independent

regulation, which can facilitate the heating and heat preservation,

which is applicable to places requiring bulking and repeated

heating.

3. Applications of IGBT steel bar / steel plate induction heating machine:

(1) Heating: mainly for carbon steel, stainless steel, alloy, brass, aluminum, etc. heating.

(2) Forging: Whole and partial induction forging for metal bar.

(3) Workpiece hot forging and rolling: standard parts, fasteners, automobile parts, small hardware, round bar and billet, etc.

(4) Specific application for the induction forging heater: bolts and nuts forging and hot upsetting, pipe induction forging and forming, auto parts (connecting rod, crank shaft, etc.), cast iron beam heating and continuous heating, oxygen bottle forging, rivet heating, long / round / square / angle bar and billet heating, etc.

4. Technical Parameters of LSW-160 IGBT steel bar / steel plate induction heating machine:

| Model | LSW-160 |

| Working Voltage | 380V, 50/60HZ |

| Max input power | 160kw |

| Oscillation frequency | 18-23KHZ |

| Duty cycle | 100% |

| Cooling water flow | 50L/Min,0.2MPa |

| Weight | 260kg |

| Dimension (L*W*H ) | 600*480*1360mm / 800*500*580mm |

| Material | stainless steel |

| Color | support customized |

| Usage | metal heating,quenching etc |