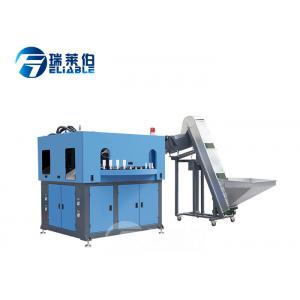

Product Details

Full Automatic Plastic PET Bottle Making Machine 2000BPH For 2

Cavity Mould

Features

- Automatic perform input and ready bottle output system. Machine for

Manufacturing Plastic Bottle

- Machine for Manufacturing Plastic Bottle adopt with the overall

structure of super-standard anti-vibration design, high-speed

operation state of the machine will shake down to a minimum.

- Plastic Bottle Blowing Machine adopts modular assembly method,

greatly decrease the local amendments due to technological

improvements when the machine is on processing.

- The structure of Machine for Manufacturing Plastic Bottle oven

adopt the international most advanced energy-saving technology of

infrared radiation heating, temperature control with automatic

negative feedback, closed-loop regulation model.

- Automation controlling item adopts international high-end computer

system, heating, collecting and measuring perform temperature with

simulation input and output module.

- Man-machine interface displays current production situation,

available for on line switching, parameter modification and

production accounting, with automatic alarm, automatic fault

detection and diagnose.

- Storing more than 7 kinds specification for making bottle.

- Adopt latest international air pneumatic. Machine for Manufacturing

Plastic Bottle

- In order to save air, we choose high pressure blowing exhaust

recovery system, which can save energy by 10-15%.

Technical Parameter

| Item | General Infomation | |

| Container | Theoretical Output | 2000pcs/hr |

| Max.container volume | 2L |

| Max.neck diameter | 45mm |

| Max.container diameter | 175mm |

| Max.container height | 350mm |

| Number of cavity | 2 Cav |

| Electrical System | Total Power | 30kw |

| Use Power | 25kw |

| Air System | Working Pressure | 1.0Mpa |

| Low Pressure Consuming | 1600L/min |

| Blow Pressure | ≤3.5Mpa |

| High Pressure Consuming | 2400L/min |

| Chiller Water | Opreating Pressure | 0.3-0.5Mpa |

| Temperature | 10-12°C |

| Flow Rate | 45L/min |

| Machine | Machine Dimension | 2.5*2.0*2.0m |

| Machine Weight | 1900kg |

| Feeding Machine Dimension | 2.0*1.0*2.0m |

| Feeding Machine Weight | 2000kgs |

Pictures Show

Main machine outlook

Shipping Details

How to get your suitable machine or production line ?

Please reply to the following questions, do it and give your

answers to us as possible as you can.

1.What kind of products will you produce?

2. What kind of product sze: volume ,height ,neck diameter

,diameter of bottle or other please inform us of details .

3. What is the capacity(per hour) you want ?

4. Single machine or whole production line .

5. Your power supply

then we can offer you more detailed quotation and other information

you need .

What Reliable Machinery Co.,Ltd can offer you ?

Our products include: Liquid filling machines (water, fruit

juice/tea, carbonated drink, oil, alcohol, plant protein drink,

etc.), Barreled filling line (3-5 gallon) Water treatment machines,

Labeling & packing machines, semi-automatic /full automatic bottle

blowing machines, and injection molding machines

Reliable Machinery can provide turn-key services for customers,

from plant layout, equipment manufacture and production line

installation to operator training and other after-sales services .

Company Profile

Taizhou Huyang Reliable Machinery Co.,Ltd

WHY CHOOSE US?

In the background of fierce competition in the machinery industry.

RELIABLE Machinery has overcome a lot of difficulty and won the

applause

of various customers with its pure-hearted developed spirit,

advanced design concept, reliable quality and perfect service and

management.

The product is exported to many countries, such as Russia, Iran,

Egypt, Brazil, Mexico, Bangladesh and so on. We believe that

Taizhou Huyang Reliable Machinery Co.,Ltd is your trustworthy

partner who is the most valuable for you to cooperate with the

factory whole heartedly wishes

to cooperate with you hand in hand and seek mutual development.