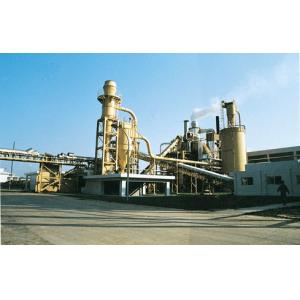

Single Opening Hot Press Particle Board (PB) Making Machine Production Line

Add to Cart

Single Opening Hot Press Particle Board (PB) Making Machine Production Line

Particle board – also known as particleboard, low-density

fibreboard (LDF), and chipboard – is an engineered wood product

manufactured from wood chips, sawmill shavings, or even sawdust,

and a synthetic resin or other suitable binder, which is pressed

and extruded. Oriented strand board, also known as flakeboard,

waferboard, or chipboard, is similar but uses machined wood flakes

offering more strength. All of these are composite materials that

belong to the spectrum of fiberboard products.

Characteristics

Particle board is cheaper, denser and more uniform than

conventional wood and plywood and is substituted for them when cost

is more important than strength and appearance. Particleboard can

be made more appealing by painting or the use of wood veneers on

visible surfaces. Though it is more dense than conventional wood,

it is the lightest and weakest type of fiberboard, except for

insulation board. Medium-density fibreboard and hardboard, also

called high-density fiberboard, are stronger and denser than

particleboard. Different grades of particleboard have different

densities, with higher density connoting greater strength and

greater resistance to failure of screw fasteners.

A significant disadvantage of particleboard is its susceptibility

to expansion and discoloration from moisture absorption,

particularly when it is not covered with paint or another sealer.

Therefore, it is rarely used outdoors or in places where there are

high levels of moisture, except in bathrooms, kitchens and

laundries, where it is commonly used as an underlayment shielded

beneath a moisture resistant continuous sheet of vinyl flooring.

In dry environments, veneered particleboard is preferred over

veneered plywood because of its stability, lower cost, and

convenience.

Chipper Section

| NO. | NAME | SPECIFICATION | QTY. | (KW) | REMARKS |

| 1001 | drum chipper | main machine dimensions: 2200*2150*1500mm | 1 | 119 | |

| 1002 | belt conveyor | dimensions: 10000×600×500mm | 1 | 2.2 | |

| 1003 | magnet | dimensions: 400×200×200mm | 1 | ||

| 1004 | chip silo | 100 m3 |

Flake Section

| NO. | NAME | SPECIFICATION | QTY. | (KW) | |

| 2001 | belt conveyor | dimensions: 6000×600×500mm | 1 | 2.2 | |

| 2002 | pulverizer | Model: 150#, electric motor: 30KW, sieve mesh number: 12, 18 Dimensions: 1300x1000x1100mm | 4 | 120 | |

| 2003 | flake pipeline | Dimensions: Ф220x7000mm | 2 | 5 | |

| 2004 | flake silo | 70m3 | 1 | 5.5 | |

| 2005 | hopper | Dimensions: 4000×5000×1000mm | 1 | ||

| 2006 | screw feeding out pipe | Dimensions: 4000×1000×500mm | 1 | 7.5 | |

| 2007 | belt conveyor | dimensions: 6000×600×500mm | 1 | 2.2 | |

| 2008 | magnet | dimensions: 400×200×200mm | 1 |

......

ITEM | INDEX |

Raw Material | Pine, Poplar, Fir |

Glue Type | MDI, PF, UF |

Hot Press | Multi-opening Press, Continuous Press (4 ft, 8 ft, 12 ft) |

Design capacity | 50000, 150000, 250000 Cubic Meters |

If you are interested, do not hesitate to contact me.

REGARDS!