Add to Cart

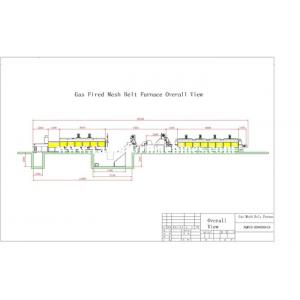

Natural Gas 250-350 KG/H Support-roller Mesh Belt Furnace For Hand Tools

General Introduction

The production line is comprised of support roller mesh belt quenching furnace, quenching tank, oil remove stand,

post-cleaning machine, support roller mesh belt tempering furnace, mesh belt cooling tank and electrical control system.

mesh belt furnace/mesh belt convyor furnace

Parameters of Energy Consumption

1 furnace working size: 600*6000*100mm; 2 rated temperature: Quenching furnace:820~920℃; quenching tank: 60~80℃; post-cleaning machine: 40~60℃; tempering furnace: 400~650℃; cooling tank: 40~80℃; 3 Furnace atmosphere: Quenching furnace: methanol+propane; Tempering furnace: air 4 Eclectic power: 380V±10%, 3phase AC, 50HZ; 1) Measurement and control: 220V±10%, 50HZ; 2) Heating system: about 48kW; 3) Driving system power and other consumption spots: about 30kW; 4) Power supply of the whole line: about 78kW; 5) Power consumption at normal working: about 25kW; 5 Gas 1) Fuel: Natural gas (8600) 2) Gas contact point pressure: 0.4-1bar 3) Heat value: 8600Kcal/m3; 4) Quenching furnace: 600KW; 5) Tempering furnace: 400KW; 6) Total natural gas consumption: 1000KW; 6 weight: 35000kg 7 Length: about 28500mm |

Products to be treated

|

Technical Specification of Mesh Belt Furnace mesh belt furnace/mesh belt conveyor furnace

The chain type mesh belt furnace adopts upper heating method. Each heating zone has a circulation fan to

achieve a unified furnace temperature. The mesh belt is driven by chain mechanism.

Furnace body:me

Quenching Furnace:

Mesh belt width :600mm;

Heating length: 6000mm;

Preheating area length: 1500mm;

Temperature control: 4-zone PID control;

Rated power: 600KW(natural gas);

Furnace temperature uniformity:≤±5℃ temperature uniformity for the same section:≤±3℃;

Furnace outer wall temperature rise: ≤50℃;

Quenching Tank:

The oil quenching tank is comprised of tank body, elevator, heating system, circulating cooling system and driving device.

The quenching medium is brightening quenching oil. The tank volume is about 8000L.

Quh belt furnace/mesh belt conveyor furnace

Oil-removing Stand:

Type: mesh belt Z type rack

Driving device

Mesh belt width: 1000mm; 1 piece;

Mesh belt: 1000*5400*2.0/3.0mm, 1 piece;

Post-cleaning Machine

The mesh belt cleaning machine has 3 working positions, immersion, jetting and air drying.

The cleaning tank body is made of steel plate and section steel by close welding.

A cover plate and a cover are arranged above it to ensure that the cleaning liquid does not flow outside.

Tempering Furnace

The mesh belt tempering furnace heats the parts from its top wall.

Each heating zone has 1 air circulation fan for improving the temperature uniformity inside the furnace.

The tempering furnace is heated by gas control which is comprised of temperature meter and PLC.

The burner is pulse ignition and has interlock device.

mesh belt furnace/mesh belt conveyor furnace