Sapphire Lift Pin For Semiconductor Ceramic Lift Pins High Purity Sapphire Pins

Add to Cart

Sapphire lift pin for semiconductor Ceramic lift pins High purity sapphire pins

Abstract of Sapphire lift pin

Sapphire lift pins are precision-engineered components widely used in

semiconductor processing equipment, particularly in wafer handling, epitaxial growth, and deposition systems such as MOCVD (Metal-Organic Chemical Vapor Deposition), PECVD (Plasma Enhanced Chemical Vapor Deposition), and other high-temperature, vacuum, or corrosive environments. Fabricated from single-crystal aluminum oxide (Al₂O₃), also known as synthetic sapphire, these lift pins are valued for their exceptional hardness, thermal stability, chemical resistance, and durability.

Properties of Sapphire lift pin

| Property | Value |

| Hardness | 9 on Mohs scale (second only to diamond) |

| Melting Point | >2,000°C |

| Thermal Conductivity | ~35 W/m·K |

| Thermal Expansion | ~5.3 × 10⁻⁶/K |

| Young's Modulus | ~345 GPa |

| Chemical Resistance | Inert to most acids, alkalis, and corrosive gases |

| Electrical | Excellent insulator |

| Optical Transparency | Transparent from UV to IR (150 nm – 5.5 μm) |

Sapphire lift pins are often custom-designed

Advantages of Sapphire Lift Pins

a. High Temperature Resistance

Sapphire maintains its mechanical strength at temperatures exceeding 1,500°C, making it well-suited for epitaxial reactors and deposition chambers where other materials may warp, oxidize, or degrade.

b. Chemical Stability

Sapphire is chemically inert in reactive and corrosive gases such as H₂, NH₃, and HF, ensuring long-term performance in CVD and etching environments.

c. Extreme Hardness

The high surface hardness resists wear and scratching from wafer contact and mechanical actuation. This minimizes particle generation and contamination.

d. Dimensional Precision

Sapphire can be machined to tight tolerances (±1 μm), ensuring consistent wafer lift height, positioning accuracy, and alignment reliability.

e. Low Particle Generation

Unlike coated ceramics or metals that may flake or outgas under thermal cycling, sapphire does not produce particulates, which is critical for cleanroom and ultra-pure process environments.

f. Long Service Life

Sapphire’s wear resistance and stability under extreme conditions contribute to lower maintenance frequency and longer equipment uptime.

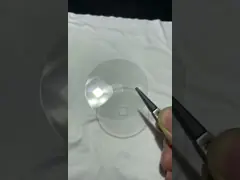

Physical image of sapphire lift pin

Applications of Sapphire Lift Pins

Sapphire lift pins are employed in a range of semiconductor and advanced material processes where wafers need to be precisely handled during fabrication. Key applications include:

a. MOCVD Systems

GaN, GaAs, and InP-based compound semiconductor growth

LED and laser diode production

Sapphire wafers and epi-ready substrates

b. PECVD and LPCVD Reactors

Wafer transfer during plasma-based thin film deposition

Used in microelectronics, solar cells, MEMS, and photonics

c. Thermal Processing Furnaces

High-temperature annealing, oxidation, or diffusion steps

d. Wafer Inspection & Handling

Mechanical systems that temporarily support or manipulate wafers

e. Etching and Cleaning Chambers

Where chemical resistance is critical during wafer pre-cleaning or stripping

Q&A

Q:What key factors should be considered when purchasing sapphire pins?

A: Application Scenario

- Material Conditions: Determine the environmental conditions the lift pins will be exposed to, such as high temperatures or corrosive environments.

- Purpose: Choose a suitable design based on the specific application (e.g., spectroscopic measurement, precision instruments, etc.).

Dimensions and Specifications

- Diameter and Length: Select the appropriate diameter and length based on the size of the samples being supported or lifted.

- Tolerance Requirements: Ensure that the lift pins meet the dimensional tolerance requirements of your application to maintain accuracy.

Related Product Recommendations