Sapphire Material AL2O3 Monocrystal 80KG 200KG 400KG KY Method LED Semiconductor

Add to Cart

Sapphire Material AL2O3 Monocrystal 80KG 200KG 400KG KY Method LED Semiconductor

Describe of Sapphire:

Sapphire ingots are aluminum oxide crystals, which are used to produce sapphire substrates, the most advantageous upstream raw material for LEDs. Under the rapid development of LEDs, the industry has entered a period of vigorous development in an all-round way. With the full penetration of the LED industry, the demand for the most upstream sapphire products will continue to maintain rapid growth and have broad development prospects. Various artificial growth techniques for sapphire crystals have been continuously developed, and more than ten crystal growth methods have been developed, such as the flame melting method, pulling method, and Kyropoulos method.

The Character of Sapphire:

1. Crystal Structure: Sapphire ingots have a hexagonal crystal

structure, characterized by strong anisotropy and high crystalline

quality.

2. Transparency: Sapphire is optically transparent in the visible

to near-infrared spectrum, making it ideal for optical applications

such as lenses, windows, and substrates.

3. Hardness: Sapphire is one of the hardest materials, ranking 9 on

the Mohs scale, making it highly scratch-resistant and durable.

4. Chemical Resistance: Sapphire is chemically inert and highly

resistant to attack from acids and alkalis, making it suitable for

harsh environments.

5. High Thermal Conductivity: Sapphire has excellent thermal

conductivity, making it useful in applications requiring good

thermal management.

6. Electrical Insulation: Sapphire is an excellent electrical

insulator, making it suitable for use in electronic components and

high-temperature applications.

7. Wide Bandgap: Sapphire has a wide bandgap, making it suitable

for optoelectronic devices such as LEDs, laser diodes, and

high-power electronics.

8. Biocompatibility: Sapphire is biocompatible and non-toxic,

making it suitable for use in medical implants and devices.

9. Precision Machining: Sapphire ingots can be precisely machined

to produce components with tight tolerances and high surface

quality.

The Form of Sapphire:

| Material | Sapphire |

| Orientation | <0001> +/-0.5o |

| Crystal Structure | Hexagonal. a=4.758 Angstroms c=12.99 Angstroms |

| Melting Point | 2040 degree C |

| Density | 3.97 gram/cm2 |

| Growth Technique | KY |

| Crystal Purity | >99.99% |

| Hardness | 9 ( Mohs) |

| Thermal Expansion: | 7.5x10-6 (/ oC) |

| Thermal Conductivity | 46.06 @ 0 oC, 25.12 @ 100 oC, 12.56 @ 400 oC ( W/(m.K) ) |

| Dielectric Constant | ~ 9.4 @300K at A axis ~ 11.58@ 300K at C axis |

| Loss Tangent at 10 GHz | < 2x10-5 at A axis, <5 x10-5 at C axis |

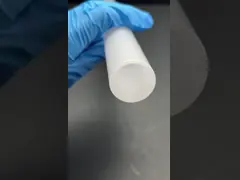

The Physical photo of Sapphire:

Application of Sapphire:

1. Optics:

Lenses and Windows: Used in high-quality optical components due to

its transparency and scratch resistance.

Watch Crystals: Utilized in luxury watches for their durability and

clarity.

2. Electronics:

Substrates: Sapphire substrates are crucial for the fabrication of

LEDs and semiconductor devices.

Insulators: Used in high-frequency applications and power

electronics due to its electrical insulation properties.

RFICs (Radio Frequency Integrated Circuits): Sapphire substrates

enhance the performance of RFICs.

3. Industrial:

Bearings and Mechanical Parts: Sapphire's hardness makes it

suitable for use in bearings and mechanical components.

Cutting Tools: Sapphire is used in precision cutting applications.

4. Aerospace and Defense:

Sensor Windows: Sapphire is used in aerospace sensors for its

durability and optical clarity.

Missile Domes: Sapphire is utilized in missile domes for its

robustness.

5. Medical:

Medical Instruments: Sapphire is used in medical devices and

surgical tools due to its biocompatibility and durability.

Endoscope Lenses: Utilized in medical imaging equipment for their

optical properties.

6. Scientific Instruments:

X-ray Windows: Sapphire is used in X-ray windows for its

transparency to X-rays.

High-pressure Cells: Sapphire is employed in high-pressure research

applications.

7. Smartphones and Wearables:

Camera Lenses: Some high-end smartphones use sapphire for camera

lens covers due to its scratch resistance.

Smartwatch Screens: Sapphire is used in some smartwatches for its

scratch-resistant properties.

8. Military Applications:

Ballistic Protection: Sapphire is used in armored vehicles and

protective gear due to its hardness.

Application Pictures of Sapphire:

The Manufacturing Process of Sapphire:

1. Crystal growth

Using a crystal growth furnace to grow large and high-quality

single-crystal sapphire crystals

2. Orientation

Ensure that the sapphire crystal is in the correct position on the rod-cutting machine to facilitate the rod-cutting process

3. Take the stick

Take out the sapphire ingot from the sapphire crystal in a specific way

4. Rolling

Use a cylindrical grinder to grind the ingot to obtain precise dimensional accuracy.

5. Quality Inspection

Ensure the quality of the ingots and whether the size and orientation of the ingots after extraction are in line with customer specifications.

Product Recommend:

1. Sapphire Wafer Al2O3 2inch 4inch 6inch 8inch 12inch

2. Wearable Sapphire Optical Windows Sapphire Glass Lens Anti High Temperature