Add to Cart

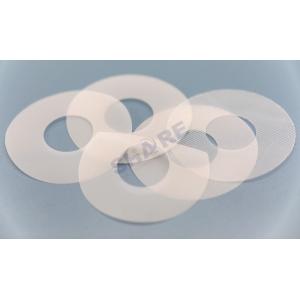

Nylon Filter Mesh Discs Shapes For Water Stream Straightener In Test Device

Share Filters Filter Mesh Options for Cutting Discs

| Material | Nylon mesh, polyester mesh, PP mesh |

| Mesh Opening | From16 micron to 1500 micron |

| Thread Diameter | From 30 micron to 500 micron |

| Open Area | From 10.2% to 60% |

| Weave Type | Plain Weave |

| After Treatment | Washing, Heat-setting, Calendaring, Water-repellent, etc |

| Size | Can cut in custom dimension and shape |

| Colour | White, or customize |

| Ref. No. | Mesh Count | Thread Diam. | Mesh Opening | Opening Area | |

| mesh/cm | mesh/inch | µm | µm | % | |

| JPP5 | 5 | 12 | 500 | 1500 | 56 |

| JPP6 | 6 | 16 | 400 | 1267 | 58 |

| JPP7 | 7 | 18 | 350 | 1079 | 57 |

| JPP8 | 8 | 20 | 350 | 900 | 52 |

| JPP9 | 9 | 24 | 250 | 860 | 60 |

| JPP10 | 10 | 25 | 300 | 700 | 49 |

| JPP12 | 12 | 30 | 250 | 583 | 49 |

| JPP12 | 12 | 30 | 300 | 533 | 41 |

| JPP14 | 14 | 35 | 300 | 414 | 34 |

| JPP16 | 16 | 40 | 200 | 425 | 46 |

| JPP16 | 16 | 40 | 250 | 375 | 36 |

| JPP20 | 20 | 50 | 150 | 350 | 49 |

| JPP20 | 20 | 50 | 200 | 300 | 36 |

| JPP24 | 24 | 60 | 150 | 267 | 41 |

| JPP28 | 28 | 70 | 120 | 237 | 44 |

| JPP30 | 30 | 76 | 120 | 213 | 41 |

| JPP32 | 32 | 80 | 100 | 213 | 46 |

| JPP36 | 36 | 90 | 100 | 178 | 41 |

| JPP40 | 40 | 100 | 100 | 150 | 36 |

| JPP43 | 43 | 110 | 80 | 152 | 43 |

| JPP48 | 48 | 120 | 80 | 130 | 38 |

| JPP56 | 56 | 140 | 60 | 120 | 44 |

| JPP59 | 59 | 150 | 60 | 110 | 42 |

| JPP64 | 64 | 160 | 60 | 100 | 37 |

| JPP72 | 72 | 180 | 50 | 90 | 41 |

| JPP80 | 80 | 200 | 50 | 75 | 36 |

| JPP100 | 100 | 250 | 40 | 60 | 36 |

| JPP120 | 120 | 305 | 40 | 43 | 25 |

| JPP130 | 130 | 330 | 40 | 37 | 23 |

| JPP140 | 140 | 355 | 30 | 38 | 33.7 |

| JPP150 | 150 | 381 | 30 | 34 | 30.25 |

| JPP165 | 165 | 420 | 30 | 28 | 20.7 |

| JPP180 | 180 | 460 | 30 | 25 | 19.5 |

| JPP200 | 200 | 510 | 30 | 16 | 10.2 |

Manufacture Process of Filter Mesh

Factory Capabilities

Share Filters sepcialize in manufacturing and offering filter mesh in different materials including nylon mesh,

polyester mesh, pp mesh, metallic mesh, and we can also convert these filter meshes to filter mesh ribbons,

filter mesh tubes, filter bags and mesh insert plastic molded filters to meet customs' Filtration demands.

Woven Filter Mesh

The width of filter mesh rolls can be in 100cm, 127cm, 150cm, 165cm, 175cm, 183cm, 365cm or

other custom width. Length of roll can be 30m, 50m, 70m, or other custom length.

Filter Mesh Slitted in Narrow Ribbons

About Us

Share Filters has over 20 years of experience developing and manufacturing filter mesh and custom product solutions

for our customer's screen and filtration needs. We can offer the filter mesh and filter components services including

slitting, cutting, welding, sewing and injection molding. Our customer base comes from a wide variety of industries

– Automotive, Home appliances, Food and beverage, Milling, Medical, Life Science and laboratory, Electronical

as well as more general engineering, giving us a wealth of experience in many areas.

Application of Share Filters Products

| Fuel filter | Cell strainer | Air purifier filter | Coffee filter | Drip irrigation filter |

| Automotive | Healthcare | Appliance | Food & Beverage | Agriculture |