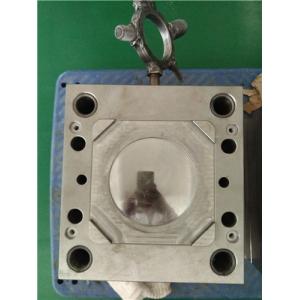

PC+ABS Plastic Injection Molds Plastic Part Injection Production Supplier

Add to Cart

PC+ABS Plastic Injection Molds Plastic Part Injection Production Supplier

1. Injection Molds Porduction

We produce:Injection Mold, prototype, Plastic injection production,mold temperature controller, Game Station Periphery Products

RFQ Need:2D, 3D drawings, samples or art works.

Mold Tooling Time:35 Working Days

Plastic injection lead time: 30-60 Days based on Quantity

Mold precision:+/-0.01mm

Mold life:0.5 million shots

2. Working Process:

Project evaluation and quotation - design validation - DFM Approval

-mold production planning- mold processing - core processing -mold

assembled and T0 production-T0 approval -

Texturing and T1 production-T1 Aprroval- Mold check and delivery.

Mould cavity: One cavity, multi-cavity or Multi parts in one mold

Mould Core material: 718,S136,NAK80,SKD61,H13,HPM

Runner system: Hot runner

Mold Base: P20,2738,2344,718,S136,8407

Finish: mirror finish, matte texturing

Mold Standard: HASCO, DME, LKM

Product material: PC+ABS,PP,PC,PA6+35% FIBER,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV, TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS.

Quality system: ISO9001:2015

3.Specifications:

| Name | Descriptions |

| Mould material | 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61 etc.(Hardness 35~55HRC) |

| Mould base | Standard mold base,LKM, HASCO ect. |

| Cavity | Single/multi |

| Runner | Hot/cold |

| Ejection system | Motor/hydraulic cylinder/stripping plate/angle pin,etc |

| Cooling system | In core baffle and in cavity plate chain drilling type cooling |

| Design software | UG, PROE, CAD, CAXA ect. |

| Plastic material | PP, PC, PS, PE, PU, PVC, ABS, PA66,PMMA, 50% ,35%,15% FIBER ect. |

| Surface treatment | Polish,texture,sandblasting,chrome |

| Mould life | 300000-500000 shots |

| Tolerance | 0.02mm -0.05mm |

| Delivery time | Sample making 3-7 days,mold making 15-40 days based on molds structure |

| Pacakge | POLYWOOD case |

| Specification | Depends on customer's DRAWINGS |

| Dimensions | 550*460*500 mm |

4. Service:

| Mold Building Lead Time: | T1, 4-5 weeks, Part measurement report (upon required). |

| Export Country: | Europe, Japan, America, Australian, UK, Canada, France, Germany, Italy...etc.: |

| Experience: | 20 years experience in plastic injection mold making and plastic prouducts produce. |

| To be discussed | In-Mold Decoration, Injection Mould, Plastic Mold, Overmould, 2K Mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold,Collapsible Core Mold, Die Sets, Compression Mold, Cold Runner System LSR Mold,...etc. |

| Mould Base Material: | LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment. |

| Surface Finish: | Texture(MT standard), High gloss polishing |

| Cavity/Core Steel: | P20, 2311, H13, 2344, Starvax 420, 236, AdC3, S136, 2312, 2379, 2316, 2083, Nak80, 2767 ...etc. |

| Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand...etc. |

| Mould Life: | 5,000 to 1,000,000 Shots. (According to your working environment.) |

| Design & Program Softwares: | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available. |

| A Grade | B Grade | C Grade | D Grade | |

| Mold base standard | HASCO/DME | LKM | LKM | Chinese Local |

| Cavity steel | H13,2344,2343, | 718,738,P20HH, | Local P20,WY718 | Aluminum,S50C |

| 8407 Heat Hard steel | NAK80 | |||

| Standard | HASCO,DME | LKM | Chinese Local | / |

| Mold life | >500,000-3000,000 | 300,000-500,000 | 100,000-300,000 | >10000 |

| Runner | Hot runner,cold runner | Hot runner,cold runner | Cold runner | Cold runner |

| Mold price | Most expensive | Expensive | Cost-effective | Cheapest |

5. Terms and condictions

| Payment terms | Mold: 40%T/T deposit, 30% T/T after T0 and 30% T/T after sample approval |

| Product: 50% deposit, 50% before shipment | |

| Trade terms | FOB Shenzhen for molds, EXWorks for Parts |

| Delivery time | Usually 30 days for molds, 25 days for products |

| Package | well packed for any damage during transport, such as pp bag or bubble bag and carton and pallet, it can be discussed |

| Minimum | 1 set for mold, 3000pcs for products |

6. Packaging Details

1. For sample: according to the dimension of the plastic parts, we

will choose a correect box to avoid the damage during the delivery.

2. For bulk:

1) One piece of plastic product with one plastic bag.

2) Putting these single plastic products into standard export

carton.

3) Pallets also can be provided if you need.

7. Injection molding applications

Household utility ware,auto components,Computer electronics,Electronics components,Field mower,Sorting Machine,Marketing samples,Medical & dental products,Model shops, toys, hobby, New product design & development,Furniture Design,Civil Engineering,Construction, Marine Industry,Garden Products,Military industry.

8. Company Brief Introduction

JDmoulding is a manufacturer of mold temperature controller and plastic injection mold manufacturers with its independent R&D, our engineering team in mold making and injection industry for more than 20 years,

we are professional in molds design and manufacturing, and solving

injection issues. JDmoulding is also an injection total solution

provider, we ensure services from mold design to finished products

launched to market.