Modular Hydrogen Production Plant Using Modified SMR Technology Hi - Tech

Brand Name:Ally Hi-Tech

Model Number:SMR

Place of Origin:China

Price:Negotiable

Packaging Details:Seaworthy Package

Technology:SMR

Contact Now

Add to Cart

Verified Supplier

Location:

Chengdu Sichuan China

Address:

201#, Changcheng Road, Chengdu, Sichuan

Supplier`s last login times:

within 3 hours

Product Details

Company Profile

Product Details

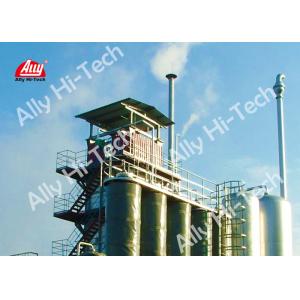

Modular Hydrogen Production Plant Using Modified SMR Technology

A modularized hydrogen-production plant developed by Ally Hi-Tech

uses a brand new version of conventional steam-methane reforming

(SMR) for hydrogen generation from natural gas. Instead of relying

on more costly ways to get product hydrogen, such as from ammonia,

methanol, or water (by electrolysis), or by truck delivery.

Features

• Long lifetime design

• Reliable operation

• High safety standard and high quality

• Fully automatic

• Pre-fabricated skids/modules

• Easy maintenance

• Reliable operation

• High safety standard and high quality

• Fully automatic

• Pre-fabricated skids/modules

• Easy maintenance

Performance

Application

This scale SMR hydrogen plant is dedicatedly developed for the

small-scale hydrogen demand, such as pharmaceuticals, chemicals,

floating glass, hydrogen filling stations.

Reference

Modular Hydrogen Production Plant Using Modified SMR Technology Hi - Tech

Inquiry Cart

0