Add to Cart

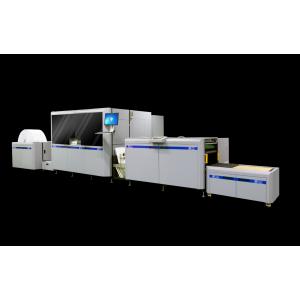

Monochrome CMYK Color Digital Inkjet Printer Web Printing Machine

Color Inkjet Web Digital Printing Machine

Shenzhen Yintech Co.,LTD is a modern high-tech enterprise specialized in pre-press plate making equipment, integrating design, R&D, manufacturing and sales services. Our main products are included:

Yintech DPM series is a high-capacity, cost-effective rotary inkjet digital printing equipment, which is latest R&D achievement of continuous research, continuous experimentation, and teamwork in the inkjet digital printing field.

Yintech DPM series is equipped with 1200*1200dpi industrial-grade

piezoelectric nozzles with core inkjet control technology, can

print duplex mino-color/dual-color/full color. Its printing quality

is as good as that of offset printing, printing speed is up to

100meters per minute, thereby meeting various printing needs.

Water based pigment ink is self-developed and produced, which can

support a wide range of printing media and provide more feasible

printing solutions of customers.

Specification for DPM560M Digital Inkjet Printer

| Printing style: | Monochrome duplex |

| Resolution: | 1200*600dpi / 1200*1200dpi |

| Max printing speed: | 100m/min |

| Front-back registration: | ±0.1mm |

| Inkjet head: | Drop-on-demand piezoelectric nozzle |

| Ink type: | Water based pigment ink |

| Drying: | Infrared drying (full automatic adjustmnet on printing speed) |

| Operation interface: | Visual operation interface |

| Max media width: | 560mm |

| Max printing width: | 540mm |

| Media thickness: | 45-165g/m² |

| Media type: | Digital printing paper, inkjet coating paper, newspaper, wall paper, etc |

| Max roll diameter: | 1.27m |

| Mechanical platform: | Max 25KW |

| Infrared drying: | Max 6KW |

| Digital control system: | Max 5.5KW |

| Temperature: | Range 22.5-27.5℃, best working temperature: 25℃ |

| Humidity: | Range 40-70%, best working humidity 50-60%RH |

| Size & Weight: | 11000*3500*2200mm, 9500kg |

Core Technology Advantages for Monochrome/Dual-color printer:

High Quality

1. High-precision nozzles splicing technology has been developed

for many years, which makes multiple nozzles splicing more simple

and faster, so that printing pattern can achieve truly seamless

connection.

2. Unique nozzle driving technology makes sure each nozzle can work

in high performance, so that the outer edge of printing text and

strokes are very round and smooth, therefore eliminating scattered

inkjet dots and burrs very well.

3. Piezoelectric high-speed industrial nozzles obtains faster and

better printing quality.

4. Multi-bit deep network technology with own intellectual property

rights enables printing quality to reach 1200dpi at a resolution of

600dpi, printing quality is as good as that of offset printing.

High Stability

1. Excellent design and high precision assembly technology have

created a high quality paper conveying platform, which makes

high-speed paper feeding more stable and motion control more

precise, thus ensuring high quality printing.

2. Advanced tension control system can control paper feedking force

at the printing position with high precision, therefore ensuring

printing stability.

3. Software and hardware system design with completely independent

intellectual property rights, high integration.

4. Self-developed ink supply system can ensure production

stability.

High Capacity

1. With self-designed buffer structure, it can perfectly match

cutting equipment.

2. Advanced typesetting technology can make prepress typesetting

more convenient and faster.

3. High speed piezoelectric industrial nozzles are used, ignition

frequency is up to 500kHz, which can obtain high quality high

printing speed 120 meter per minute.

Cost Effective

1. Self-developed brand "FU CAI" series ink can highly match

Print-On-Demand printing, and cost effective.The printing product

is colorful, strong contrast, compatible with a variety of papers,

durable, and no fading.

2. Stable high production capacity, extremely low rejection rate.

3. Advanced intelligent ink distribution system greatly reduces ink

consumption while printing high quality products.

4. The digital printing equipment has a longer lifetime,

outperforming traditional printing equipment, and a lower

maintenance cost.

Yintech Digital Printing and Cutting System

1. Fast Production

Maimum production speed can reach 137 meters per minute, after

connecting inkjet equipment, it can guarantee production speed

requirement of 100 meters per minute.

2. Domestic Leading Cutting Technology

Domestic leading cutting technology can meet thin paper cutting

requirement, unique small-diameter rotary cutting knife can ensure

smaller size precise cutting.

3. Simple Setting and Quick Specification Conversion

Only making a simple setting on the touch screen can adjust paper

cutting specification, fine adjustment without downtime, thereby

improving efficiency and reducing paper waste.

4. Dislocation Stacking, Convenient for Post-process Operation

Simple touch screen setting can realize dislocation stacking, no

need for sub-tasks in the post-process, thus reducing labor cost

and improving production efficiency.