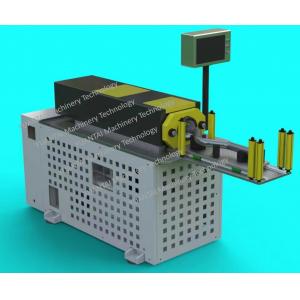

Low Cost Tube End Forming Machine Servo Die Changing Four / Six Station

Add to Cart

TM-20T-4/6 Station tube end forming machine (20T type)

| main technical parameter | |

| Max suitable tube size | Φ80 |

| Max working stroke | 160mm |

| Hydraulic power | 20Ton |

| Station | 4 or 6 |

| Servo Die change speed | 0.05mm |

| working speed | 3-4sec |

| Machine characteristics |

| (1) PLC control, hydraulic drive, stable operation |

| (2) Touch screen control |

| (3) Mobile pedal switch with automatic, tight stop,continue three consecutive modes |

| (4) Four / six station, servo die changing, high speed and precision |

| (5) Die replacement is simple and suitable for elastic production |

| (6) Can shrink tube, expand tube, tampering process. |

Advantages:

1. Low cost for operator training,high production effeciency and product uniformity.

2. Drived by electric servo motors.compared with hydraulic drive,it has higher stability and longer lifetime.It is unnecessary to worry about oil-leak or working temperature.

3. Gapless tube bending,with long-time high precision and processing efficiency,easy for operation.It has good compatibility.

4. Small in size,low noise level

5. Low running cost,with best cost performance for tube processing.

6. Widely used in small-diameter tube processing,for example tubes of air conditioner and oil tube for autos

Standard models:1~5 stacks,4~6 servo motors

Advanced motor:11 fully electric servo motors

Applications:

Auto,motorbike,aircraft,bicycle,kids bike,fitness equipment,furniture,outdoor equipment,air conditioner,food machinery,nulcear tube such as reactor,evaporator and heat exchanger

Features

1. The electric control system uses famous Japanese controllers,such as servo drivers,servo motors,positioning modules and CPUs manufatured by the Mitsubishi Corporation,and is high in performance and good stability.

2. The Mitsubishi ultra-large CPU can accommodate 400 groups of files for compiling,if necessary,the additional transmission software is bought and installed in the computer,and the documents and files are stored in the hard disk,so that the number of compiling groups is unlimitedly expanded.

3. Industrial-use computer type:the WINDOWS operating system is internally installed,and used together with the Mitsubishi servo system,besides the Mitsubishi servo driving,the convenient file management owned by the WINDOWS operating system is also provided;and the files can be storted in the hard disk or soft disk,so that the compiling groupnumber is unlimitedly expanded.

4. Automatic 3D simulation function for tube-forming is selected as required.

5. An automatic error-fault detecting function is provided,and the errors and faults are displayed on the screen,so that the operator can much easily troubleshoot.

6. Automatic 3D simulation function for detecting interferring position is selected as required.

7. All processing data are inputted by the touch screen

8. Based on the change of materials,each curve is set with a compensation value,a speed and a demoulding gap.

9. Each curve of one tube can be programmed with five action sequences and ten-stage speeds,so that the processing efficiency is improved,and the interference point is reduced.

10. Chinese/English language are switched to display on the touch screen,and customers can also purchase the machine installed with other languages