Add to Cart

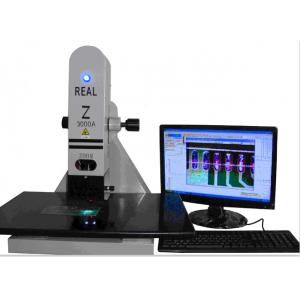

3D Optical Measurement System , Digital Video Measurement System

Applicability:

3D Optical Measuring System can complete all the measuring request and especially fit for the workshop and measurement lab,widely used in aviation, aerospace, defense, automotive, mold and electronics industries,etc.

Main features:

1.Closed frame structure which is simple and compact.

2.Crossbeam’s adoption of precise designing technology of inclined girder (patent) guarantees the machine’s lightweight,low center of gravity,strong rigidity and small error in motion to ensure the machine's stability.

3. Z-axis using cylinder balancing device ,greatly improved the Z-axis positioning accuracy and stability.

4. Drive system uses the internationally famous brands of high-performance DC servo motors,toothed belt drive device to ensure the transmission faster and more accurate,better sports performance.

5. SB-Specific coordinate control system to guarantee the movement stability,21 geometric error correction technology.

6. The software used with independent intellectual property rights, the powerful AC-DMIS measurement software package, its perfect measurement functions and online features provides users with the perfect measurement solution.

Main Functions of 3D Optical Measuring System

1) Configuration of measuring environment parameter and movement parameter.

2) Probing system configuration and calibration.

3) Capture of measuring point.

4) Basic geometry element.

5) Element’s formation, transformation, review, projection, storage, transfer and relevant calculation.

6) Setup, storage and transformation of coordinate system and work piece coordinate system.

7) Assessment of dimension tolerance and position tolerance.

8) Store and input of measuring result file.

9) Import and convert CAD 3D model.

10) Coherence between Model coordinate system and part coordinate system.

11) Pickup of Features and curved surface points on the model.

12) Creation and measurement of section surface line.

13) Creation and measurement of curved surface.

14) Offline Programming based on CAD model

Character : (specimen stay and double column moving)

Full automatic Double Column Type High Accuracy Video Measuring Instrument

Machine base adopt marble (00 level), solid testing platform design, make sure high stability and rigidity.

Adopt Japan THK grinding ball screw & THK precision guide rail, Panasonic high performance servo system full-closed control, high accuracy, high speed, high stability.

Adopt USA TEO high resolution colorful industrial 800 TV wire on CCD.

Make sure high quality testing image and quick testing speed.

Full automatic zoom lens, no need to measurement after changing the lens zoom.

Program tetracyclic eight zone LED surface cold light, direct-axis rim cold light, (coaxial cold light for option)

Germany Heidenhain open type SMT optic scale 0.0005mm

England Renishaw touchable measuring head (Auto probe SCR system for option) and Japan Keyence Laser probe.

Powerful functional R&D full automatic 3D measuring software, can auto test by program.

Video, probe, laser test coaxial, can auto test by program.

Can option Z axis measuring range: 300-500mm