Add to Cart

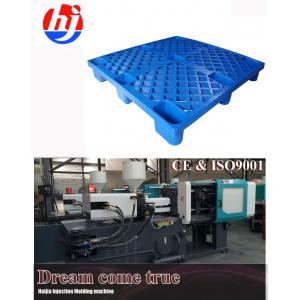

plastic pallets injection molding machine manufacturer good quality mould production line in ningbo

HAIJIANG plastic parts injection machine features:

→ bigger space between tie-bars

→ central-clamping structure

→ famous components

→ energy saving with servo motor

→ low noise, fast respons

→ high precision, Stable and super long life

→ T-Slot Platen

→ abundant Spare Parts

→ better price

Clamping Unit:

1. Optimized Platen Design with high rigidity and enlarged space

between tie bars

2. Euromap-based Platen Layout with both T-slot & tap holes,

locating design in moving platen to better suit various molds

3. New ejection system design with longer ejection stroke, bigger

space and better rigidity

4. Hydraulic drivien gear-type mold height adjustion mechanism

5. Relocation of mechanical safety interlock for easier operation

6. linkage structure for front connecting rod increases

connectingrod's strength greatly, as well as the whole clamping

unit's rigidity & accuracy.

HIGHLY RIGID INJECTION UNIT GUIDANCE

1.Optimized clamping unit provides lower energy consumption and faster movements for reduced cycle times.

2.The redesigned toggle kinematics for higher efficiency and lower

energy consumption for small and large machines.

3.The redesigned clamping unit providing lower platen stress and

higher mold force stability, reducing mold wear and improving

molded product stability.

4.Fixed platen with centralized force loading and less platen flexing. Redesigned moving platen providing centralized force distribution from the toggle system to the mold. The result: higher rigidity and stability.

5.Providing better lubrication and lower lubrication consumption. A smooth operation leads to longer lifetime of the clamp. Less maintenance required.

6.Due to new toggle design with optimized kinematics.

Take 200-ton clamping unit for example

Vm: Moving speed of movable platen

Vo: Moving speed of oil cylinder

The rigid one-piece injection base supports the common slide rail for injection and screw movements.

| SPECIFICATION | HJF-780 | ||||

| A | B | C | D | ||

| Screw Diameter | Mm | 90 | 95 | 105 | 110 |

| Screw L/D Ration | L/D | 23.2 | 22 | 19.9 | 19 |

| Shot Size(Theoretical) | cm3 | 2924 | 3258 | 3981 | 4369 |

| Injection Weight(PS) | g | 2632 | 2933 | 3583 | 3932 |

| Injection Rate | g/s | 574 | 640 | 781 | 858 |

| Injection Pressure | MPa | 195 | 175 | 143 | 130 |

| Screw Speed | rpm | 115 | |||

| Clamp tonnage | KN | 7800 | |||

| Opening stroke | Mm | 950 | |||

| Space Between Tie Bars | mm | 980*950 | |||

| Max.Mold Height | mm | 960 | |||

| Min.Mold Height | mm | 400 | |||

| Ejector Stroke | mm | 280 | |||

| Ejector Tonnage | KN | 186 | |||

| Max.Pump Pressure | MPa | 16 | |||

| Pump Motor Power | KW | 37+30 | |||

| Heater power | KW | 56.7 | |||

| Machine Dimension(L*W*H) | M | 11.43*2.40*3.14 | |||

| Machine weight | T | 37 | |||

| Oil Tank Capacity | L | 1500 | |||