Tooling Plate Pure AZ31 Mig Welding Wire Sizes with 1.2mm For TV , Camera

Add to Cart

Tooling Plate Pure AZ31 Mig Welding Wire Sizes with 1.2mm For TV , Camera

Specification

Magnesium Alloy AZ31,AZ61,AZ91,AZ80,WE43 is available in Plate, Tooling Plate, Sheet, Rod and Bar.

Standard diameters: 1.2mm, 1.6mm, 2.0mm, 2.4mm, 3.0mm

Meet ASTM B90 Standard!

Chemical Composition

The chemical composition of magnesium Elektron WE43 alloy is outlined in the following table.

| Element | Content(%) |

| Yttrium, Y | 3.7-4.3 |

| Rare Earths | 2.4-4.4 |

| Zirconium, Zr | 0.4 |

| Magnesium, Mg | Remainder |

Advantage

- 4 to 5 times greater tool life,

- Up to 5 times more machinable than rolled aluminum, machine dry, without oil or chemicals,

- easier handling saves time and energy,

- eliminates surface machining, with no stress relief after machining process;

- no warps and is dent resistant,

- strong weldments - up to 95% of parent metal

Application

Engineering industry:Power systems;aircraft manufacturing

automobile industry:Helicopter transmissions;Computer parts;painting and engraving.

Military industry:Missiles

Packaging

Every reel is packed in vacuum foil package, the reels are packed in wooden case.

Note: Product specification are tailored to customer's

requirements.

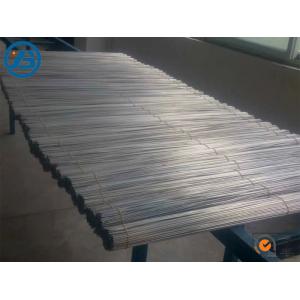

Magnesium Welding Wire show

Service

- provide customers with the highest-quality magnesium alloyto achieve their goals.

- Our flexibility is in meeting customer requirements and our superior customer service.

- We provide high quality, quick-turn assembly.

- We help customers qualify your designs and provide quality samples to your customers.

Workshop

Quality inspection

1. Appearance inspection: Check the installation and welding of the original

2. Component push pull test: use push pull meter to check the welding and fastness of components

3. Rigorous testing: Each product must be tested before it can be shipped.

Testing Equipment

Certificate

We have attained ISO9001 and ISO14001 certificates, Standardize and improve the enterprise quality management system.

Why choose us?

1. Your enquiry can be replied in 24 working hours;

2. Well-trained and experienced staffs to answer all your enquires

in fluent English;

3. OEM&ODM, we can help you to design and put into product;

4. Protection of your sales area, ideas of design and all your

private information.

FAQ

Q1. What about the lead time?

A : 1-7 business days for sample orders; Hot model generaly can be

shipped within 3 business days . 15-20 business days for bulk

order .

Q2. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5

days to arrive. Airline and sea shipping also optional.

Q3. Do you guarantee the products?

A : Yes, we offer a 24-months warranty.