Add to Cart

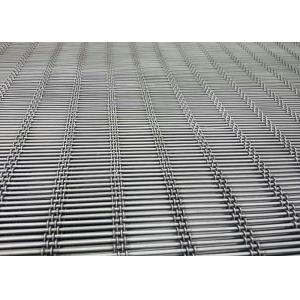

product details of Self Cleaning Screen Mesh

woven wire flooring is made from heavy duty wire. The high quality

finish and superior tensile strength, when compared to other types

of decking, ensures Locker Group woven wire flooring is the number

one choice in rural flooring

Specifications of self cleaning screen mesh

| aperture | wire diameter | Sheet Size max width 2400mm | weight/m2 |

| 10x50mm | 5mm | Made to order | 15 |

| 10x50mm | 5mm | Made to order | 15 |

| 10x50mm | 6.3mm | Made to order | 23 |

| 10x50mm | 6.3mm | Made to order | 23 |

| 10x70mm | 6.3mm | Made to order | 22 |

| 12x70mm | 6.3mm | Made to order | 20 |

| 15x100mm | 8.0mm | Made to order | 15 |

Common Applications of self cleaning screen mesh

• Abattoirs • Stock Transport • Farrowing pens • Weaner Crates •

Bacon/Grower Pens

Benefits

Self Cleaning Floor – Reduces cleaning time as well as reducing the risk of disease

harbouring organisms. In addition the open weave

pattern allows waste to pass through the mesh easily, virtually

eliminating the problem of dirty, slippery floors.

Comfort and Foot Hold – The smooth round wires are comfortable to lie on, yet the crimp

of the wire gives a secure foot hold to both sow

and piglet.

Easy Installation and Long Life – pig flooring is made to order, so you don’t pay for expensive

wastage. Plus, designed specifically for

each project, floors are easy to install. Improved Ventilation –

Locker Group wire floors allow increased ventilation compared to

traditional

timber grid floors, helping to reduce both labour and material

costs.

Installation Recommendations

1. 25mm N.B. pipe is an ideal bearer. Its rounded surface sheds the

effluent more readily, and is therefore less susceptible to

corrosion.

As further assurance against corrosion, it is suggested that both

ends of all pipes be flattened and welded to seal and prevent

internal corrosion.

2. Flat Bar on Edge is as satisfactory a support as pipe. It has

load bearing strength and presents a minimum surface area, thus

minimizing the

effects of effluent build up. Its profile permits fabrication with

the least amount of labour.

3. It has been determined that edges, corners, the rim of drilled

holes and cut edges are more prone to corrosion. The flushing of

pits daily and

provision of adequate ventilation will assist in extending the life

of these metal components.

4. Whilst hot dipped galvanizing should be successful, it is not

advisable due to the warping and twisting that may occur. In

addition, sharp pointed

‘dags’ of galvanizing may protrude into the aperture resulting in

cuts, infection and general discomfort.

5. It is suggested that the support spacings on pipe should be

around 380mm for high tensile and no more than 300mm for stainless

steel mesh.

These suggested spacings are subject to live weight loadings.