Product Details

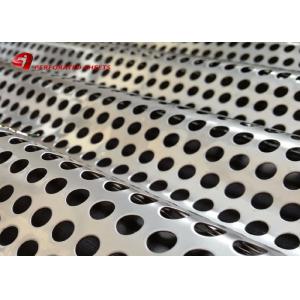

Galvanized or Powder Coated Perforated Corrugated Metal Sheet for

Roofing

Apart from perforated windbreak panels, we also supply another type

perforated corrugated sheet. Corrugated perforation sheets allow you to create a favorable

acoustic environment, and significantly reduce the noise level in

areas of industrial and civil purposes. The sound wave easily

penetrates through the holes can not go back, repeatedly reflected

from the inner surface of the metal.

Usage:

- Perforated corrugated steel sheet is the ideal sound insulation

material mounted on the ceiling or wall of the room, to offer the

best solution to create a favorable acoustic environment indoors,

as well as an overall reduction of noise in the building.

- Corrugated perforated metal sheet, also commonly used in the

manufacture of noise barriers designed to shield sources of

excessive noise: roads, railways, subway open overpasses, tunnels,

shooting ranges, shooting, stadiums, airports and more.

- It also can be used as highly ventilated facades, windbreak panels

and shade cover.

SPECIFICATION

- Material: aluminium, aluminium alloy, galvanized steel, stainless

steel, copper or brass.

- Thickness: 0.3–12 mm.

- Width: 0.8–1.3 m.

- Length: 2.5, 3 m.

- Hole Diameter: 5–100 mm.

- Hole Arrangement Mode: straight, staggered.

- Staggered Center: 0.125–1.875 mm.

- Mesh Opening Area: 7% – 83%.

- Pattern Design: available.

- Configuration: Symmetrically or asymmetrically.

- Surface Treatment: standard, anodic oxidation, galvanized, powder

coating or fluorine carbon spraying.

- Package: packed with plastic film, shipped by pallets or according

to customers' requirements.

Galvanized perforated corrugated sheet | Perforated corrugated sheet in 4mm thickness |

Perforated corrugated sheet | Perforated corrugated sheet |

Spanning

the panels may be subjected to loads from impact or limited by

acceptable deflection. Maximum recommended spans in millimeters for

each profile are as shown in the following table. For most expected

applications the panels will not be subjected to wind or foot

traffic loading. However if either should be applicable refer to

the profile specific Product Technical Manual for these capacities.

| Profile | Ceiling

Applications | Non-Impact

Areas of Walls | Possible Impact

Areas of Walls | | Longspan | 1200 | 1500 | 1200 | | Monoclad | 1200 | 1500 | 1200 | | Corrugated | 1200 | 1200 | 900 | | K-Panel | 900 | 900 | 600 |

|

ADVANTAGES OF PERFORATED CORRUGATED METAL PANELS

- Virtually endless choice of hole sizes, shapes and patterns

- Multiple corrugation patterns/profiles available

- Choice of materials, colors, finishes and protective coatings

- Customization available to meet your creative designs

- Environmentally responsible materials

- LEED credit(s) may be earned with corrugated metal panels

- Expert design and engineering assistance available

- Easy installation and maintenance

perforated corrugated sheet

perforated corrugated sheet

perforated corrugated sheet

perforated corrugated sheet

Company Profile

Hebei Qijie Wire Mesh MFG Co., Ltd. is located in Anping county, Northern China, which is famous as

"the hometown of wire mesh" in the country.

The company was founded in 1999 with a registered capital of

500,000 US dollars, covering 40,000 square meters, has 3 plant

areas, 22 stainless steel woven mesh machines, 28 welded wire mesh

machines, 11 double twisted hexagonal gabion baskets machines, 8

cutting and flattening mesh machines, and 2 automatic PVC coating

lines. Qijie does sales both home and abroad with annual amount of

more than $ 20 million, the main products are stainless steel fly

screen mesh, fence panels, gabion baskets, woven screening mesh,

welded wire mesh, expanded metal mesh, perforated metal and various

wire products.

Our main aim is to ensure customer satisfaction by providing

superior quality products at reasonable prices. We use meticulous

quality control procedures and analysis in order to ensure our

products meet the international standards. A combination of

competitive prices, on-time delivery and quality guarantee will

make us our customer's best choice.