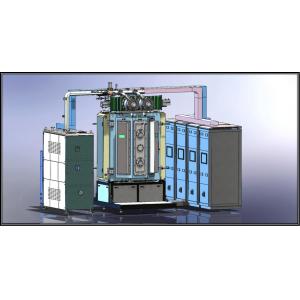

PECVD DLC Thin Film Vacuum Coating Equipment, Graphite sputtering deposition system

Add to Cart

DLC Thin Film Vacuum Coating Equipment, Ion Source PECVD to Generate Diamond Like Carbon Coating System

DLC film ( Diamond - Like - Carbon), it has been benefiting variety of industries for high end quality products like: automotive bearings, medical instruments, military, aerospace, industrial sealing parts, watches, etc. which require high durability and min. coefficient of friction.

PECVD + PVD process DLC coating technique has been developed by us for years to satisfy the highest standard application. This process providing an unique and flawless finishing on the product surface except extrodiary beauty.

DLC Thin Film Coating Machine Specifications

| MODEL | RTSP1010 | |||||||

| TECHNOLOGY | PECVD process- magnetron sputtering + ion source | |||||||

| CHAMBER MATERIAL | Stainless Steel (S304) | |||||||

| CHAMBER SIZE | Φ1000*1000mm (H) | |||||||

| CHAMBER TYPE | Regular octahedron chamber, 2-doors | |||||||

| ROTATION RACK & JIG SYSTEM | 6 (8)satellite, Max. weight: 400kgs | |||||||

| POWER SUPPLIES | Qty. of Sputtering: 2*24 KW Bias of Power Supply: 1*24W AE power supply for option Ion Source Power supply 2 sets, AE power supply for option | |||||||

| DEPOSITION MATERIAL | Cr/C | |||||||

| DEPOSITION SOURCE | 2 pairs (4 pieces) Sputtering Cathodes + 2 Ion Source Coating Area: Dia800mm*H550mm; Uniformity Area: ±10~15% | |||||||

| CONTROL | PLC(Programmable Logic Controller) + Touch Screen ( manual+ auto+ semi-auto operation models) | |||||||

| PUMP SYSTEM | Rotary Vane Pump: SV300B - 1 set (Leybold) | |||||||

| Roots Pump: WAU1001 - 1 set (Leybold) | ||||||||

| Holding Pump: D60C-1set- (Leybold) | ||||||||

| Magnetric Rotor Suspension Molecular Pump: MAG2200 - 2 sets (Leybold) | ||||||||

| GAS MASS FLOW CONTROLLER | 3 channels, Made in America (MKS brand) | |||||||

| VACUUM GAUGE | Model: ZDF-X-LE, Made in China | |||||||

| Linear Ion Source | 2 pieces Pre-treating, plasma cleaning + assisted deposition | |||||||

| SAFETY SYSTEM | Numerous safety interlocks to protect operators and equipment | |||||||

| HEATING | Heaters: 20KW. Max. temp.: 400℃ | |||||||

| COOLING | Industrial Chiller (Cold Water) | |||||||

| POWER MAX. | 100KW (Approx.) | |||||||

| AVERAGE POWER CONSUMPTION | 45 KW (Approx.) | |||||||

| GROSS WEIGHT | T (Approx.) | |||||||

| FOOT PRINT | ( L*W*H) 4000*4000 *4000 MM | |||||||

| POWER ELECTRICAL | AC 380V/3 phases/50HZ | |||||||

Please contact us for more specifications, Royal Technology is honored to provide you total coating solutions.