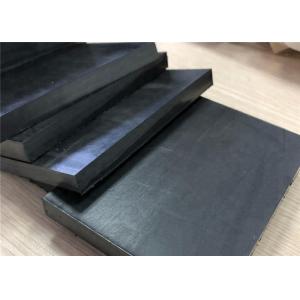

Anti Static Injection Molded Parts Plate Graphite Acrylic Filled PTFE Mould Sheets

Add to Cart

PTFE sheet molded board, plate, Graphite acrylic Filled PTFE Mould Sheets

Product Description

PTFE panel (also called PTFE Sheet, board, plate) molding and turning points are two kinds of PTFE resin molded plate is made by molding method at room temperature molding, and then by sintering, cooling made. plastic materials PTFE resin cutting boards(PTFE panel) made by compacts, sintering, peeling from. Its products versatile, has a very excellent overall performance: high and low temperature (-192 ℃ -260 ℃), corrosion resistance (acid, alkali, aqua regia, etc.), weather-resistant, high insulation, high lubrication, non-sticking, non-toxic, and other fine features.

| Product name | plate |

| Material | PTFE, 100% PTFE powder |

| Mold Processing: | NC Machined,Lathe,Turning,Stamping,Casting,Injection |

| Color | White,black,or as your requirement |

| Mold style | Compression,extrusion,injection |

| Size | customized, standard or nonstandard |

| Temperature | -180 ° C to +260 ° C |

| Advantages | 1.Non-stick 2.temperature resistance 3.low enlongation 4.anti-static 5.chemical resistance |

| Packing | Inner plastic bag,outside carton box,last is the pallet,all are based on the customers' requirments |

| Appllication | Auto spare parts,Motorcycle,Bike,Industrial equipment,Medical equipment,Robot,Solar energy,UAV,Security equipment,and so on |

| Port | Qingdao, etc |

Where is board Application ?

Seats

Bellows

Bushes

O-Rings

Chevrons

Valve Seats

Wear plates

Slide bearings

Linings (chemical)

Envelope Gaskets

Bearings in chemical pumps

Electrical and thermal insulators

Piston Rings, glide rings, lantern rings and back up rings

Steps:

1.Negotiations: Quality,material,price,payment,delivery time item

and so on.

2.Place an order: According customers drawing or sample.

3.R&D: According customers requirement design or improve 3D

modeling.

4.Designconfirmation: We send 3D drawing to customer to

confirme.Before we make the mould.

5.Mould processing: CNC EDM machine processing then assembly and

trial.

6.Sample confirm: We will send trial sample to customers.Before

shipment,If the sample isn’t satisfied customers.We will modify

mould until customers satisfaction.

7.Mass production: If customers need mass production plastic

products,We can offer.

8.Manufacture

9.Package and Delivery

FAQ

1. How to produce ?

we can produce according to seal type and sizes .

if you need some customized parts, we can produce according to

drawing and samples.

2How to make the order?

You can send us email or inquiry at alibaba directly.

3. What is your main market?

Our main market is north America, UK, Australia, Middle East , Europe.

4. Do you provide samples ? is it free or extra ?

We can supply you free samples without extra charges, but express cost is for buyer's

account.

5. How is the quality?

Strict control when production, 100% inspection before shipment.