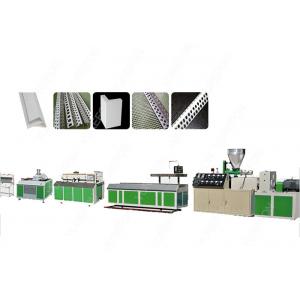

20 M Plastic PVC Profile Extrusion Line For Wall Ceiling Corner Tile Making

Add to Cart

Plastic Pvc Profile Extrusion Production Line, PVC Ceiling Corner Tile Making Machine For Wall Corner

Description of PVC Ceiling Corner Tile Making Machine:

PVC Corners Production Line consists of twin-screw extruder or

single-screw extruder, vacuum stereotypes table, haul-off machine,

punching machine, cutter and stacker. It can be one out of four or

one out of six, high output and achieve online punching, which

saving time and effort and easy to operate.

Process Flow of PVC Ceiling Corner Tile Making Machine:

Raw material +wood power+ additive → mixing → granulating → conical

twin-screw extruder → profile extrusion mould → cool molding die →

vacuum calibration support → belt haul-off → cutter → rack →

finished product inspecting & packing

Raw materials for PVC Corner :

PVC + calcium + other additives.

PVC high chemical stability,panels can be used for a long time.

Feeder | • To feed material into extruder; |

Extruder | •World famous brand electrical component: Siemens,Schneider, ABB

etc; |

Die head | • 3Cr13/3Cr17 material |

calibration table | • Include full set of vacuum and water pump |

Haul off | • Upper/lower caterpillar driven separately and speed control by

inverter |

Cutter | • Lifting saw cutter with adopts double station dust collection

system |

Stacker | • Stainless steel304 as touching material |

Hot stamping machine | • Decorative pattern and film protection of product surface |

Technical information:

Parts | No. | Name | Brand |

1 Screw and barrel | 1 | Design | German design |

2 | Main materials | 38CrMoALA | |

3 | Screw heating | Silicon oil heating | |

4 | Barrel heater | Cast aluminum heater | |

5 | Barrel has vacuum exhausting system | ||

2 Driving parts | 1 | Main motor | Siemens Brand |

2 | Gear box | Top brand in China | |

3 Electric parts | 1 | Inverter | ABB brand |

2 | Contactor | Schneider brand | |

3 | Relay | Schneider brand | |

4 | Breaker | Delixi brand | |

5 | Temperature meter | RKC brand | |

6 | Hauling motor | Densen brand | |

7 | Hauling gear box | Hard surface gear box | |

8 | Vacuum pump | Yvhuang brand | |

9 | Water pump | Yvhuang brand | |

10 | Cutting motor | Siemens brand | |

11 | PLC | Schneider brand | |

4 Mechanical parts | We use CNC machines to ensure the precision of our mechanical parts | ||

5 Protection system | We have a whole set of protection system for our machines, such as: | ||

For more technical information please contact us by email. | |||