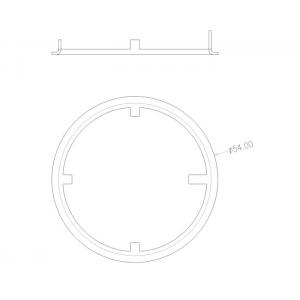

Progressive Die And Stamping Round Brass Circle Ring Parts For Internal Linking Power End

Add to Cart

Metal stamping is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a punching machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive dies are commonly feed from a coil of steel, coil reel for unwinding of coil to a straightener to level the coil and then into a feeder which advances the material into the press and die at a predetermined feed length. Depending on part complexity, the number of stations in the die can be determined.

Stamping is usually done on cold metal sheet. See Forging for hot metal forming operations.

This stamping parts is for Auto parts with high precision.We supply

including ordinary stamping, precision high-speed stamping, laser

cutting,

drilling, tapping, CNC processing, laser welding, butt welding,

argon arc welding, CNC turning, surface

grinder processing, cylindrical grinder processing, mirror polish

processing, etc

|

Details show: