Double Screw Extruder Plastic Recycling Pellet Machine 100-1000kg/Hr Capacity

Brand Name:YAOAN

Certification:CE

Model Number:72MM

Minimum Order Quantity:1

Delivery Time:30-90 DAYS

Payment Terms:TT,LC

Contact Now

Add to Cart

Verified Supplier

Location:

Dongguan Guangdong China

Address:

10#,Zone 1,Fumin industrial park,Dalang town,Dongguan city,Guangdong province,China

Supplier`s last login times:

within 1 hours

Product Details

Company Profile

Product Details

Parallel Co-rotating Twin Screw Extruder Line For PE, PP, ABS, AS, PA, EVA, PET Materials

- Mixing nature-changing: PE,PP,PS+SBS;PA+EPDM;PP+NBR;EVA+Silicon rubber,etc.

PE,PA,PC,CEP+ABS(alloy);PBT+PET;PP+PE,etc.

- Filling nature-changing: PE,PP,EVA etc+aluminum hydroxide,magnesium hydroxide,antimony oxide.

PP,PA,ABS+ferrous powder, sulphuric powder, ceramic powder

- Colored machine pellets: PE,PP,ABS,AS,PA,EVA,PET etc+long fires,small fibres, carbon fibres, crystals and so on, etc.

2. Features of extruder

(1) Barrel

- euro-style rectangle barrl, reflux refrigeration channel is optimized and disposed,which makes temperature difference in D areas smaller.

- innovated design of heater tightened style insures high efficiency of heat transfer and high longevity of heater.

- the material is used high quality nitrided steel ,corrosion proof or antifriction with correspounding process.

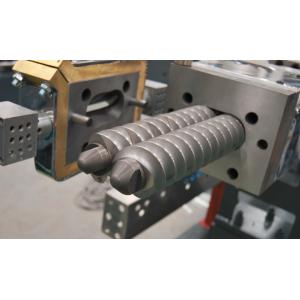

(2) screw

---.the screw is made of high tool steel 38 CrMoALA or W6Mo5Cr4V2 by special heat-treatment , which is possessed with high corrosion-resistat and high functions

(3)metering feeders

- various metering feeders --- single screw ,twin screw ,hollow screw,forced-feeding, side- feeding.

(4) new-style gear transmission system

- new-style project of parallel three-axises driving makes the conve axis,convey

- chain,decelerate and torque get together ,which keep it compact ,and the key bearings are imported

- soakage and spraying lubriation integrate smoothly

- technics,strengthening of tooth face,so they can ensure high torque,high precision and low noise

- the selecte material of drive components is dainty,including super intention alloy cementiteing steel,cementiting and grinding.

(5) electric control cabinet

- frame structure control cabinet

- imported electrical elements

- imported temperature control system

- imported driving system

- interlock and multi-protection

- adopting imported PLC(OMRON or SIMES) to achieve optimized process control. stronger function,steady performance and much higher accurancy

- it can be also accomplished full-set link-lock protection,trouble safeguard,fault alarm cluing and so on

- operation interface on touching screen is visual and marked ,which is brief and easy to use.

(6) pelletizing system

---.various modes of pelletizing,such as water-cooling strand,air-cooling pelletizing,water-ring pelletizing,under water pelletizing

3. Parameter table of twin screw extruder

| Model | Screw Diameter D(mm) | L/D | Screw Rotation N(r/min) | Motor Power P(kw) | Screw Torque T(N.m) | Torque Rating | Output Q(kg/h) | |||

| TSE-75A | 71 | 32-56 | 400 | 90 | 1074 | 4.9 | 250-350 | |||

| 500 | 110 | 1050 | 4.8 | 300-420 | ||||||

| TSE-75B | 71 | 32-64 | 600 | 132 | 1050 | 4.8 | 350-550 | |||

| TSE-75C | 62.4 | 32-64 | 600 | 160 | 1273 | 5.8 | 400-600 | |||

| TSE-75D | 71 | 32-64 | 600 | 200-250 | 1990 | 9.2 | 500-1000 | |||

Double Screw Extruder Plastic Recycling Pellet Machine 100-1000kg/Hr Capacity

Inquiry Cart

0