Add to Cart

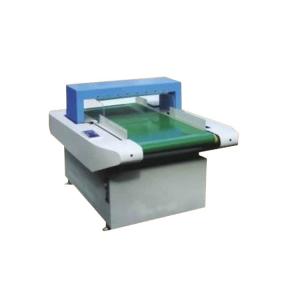

High immunity Detector DSP Automation Needle Detector Machine

1.Description:

High immunity Detector DSP Automation Needle Detector Machine detection of thick material and thin material, display of the

positions of broken needles and scrap iron in an object being

detected for facilitating the finding of the broken needles of

operators, automatic return of object to be detected, automatic

start-up, once switch startingfir each working stage, a power

utilization system capable of stopping the machine five minutes

after no-load operation, power and money conservation, power

utilization safety protection, great popularity among customers.

2.Applicable Industries:

High immunity Detector DSP Automation Needle Detector Machine is used to garment, textile, bra, baby product, shoes, socks,

gloves and soon, for detecting impurities such as needle points,

pins and scrap iron in products, preventing metal pollution of the

products and guaranteeing product quality.

3.Technical Parameters:

| Detection width | 400mm | |||||

| Detection height | 100mm | 150mm | 200mm | 240mm | 280mm | 320mm |

| Detection sensitivity Fe (iron) | FeΦ1.0mm | FeΦ1.2mm | FeΦ1.5mm | FeΦ2.0mm | FeΦ2.5mm | FeΦ3.0mm |

| speed | 25m/min | |||||

| Power supply | AC220V±10% 50Hz | |||||

| Power | 60w | |||||

| Weight | 120KG | |||||

| Dimensions l*w*h (mm) | 1250*800*850mm | |||||

Features:

1,Neuest design with luxury modern looking streamline ABS cover.

2,Broken readle location indicater (8 sector).

3,Appear the passing sum.

4,Including extra-thick and exera-thin inspection function.

5,Belt correct device.

6,Automatically startup function.

7,EP design of autematically stop function after each 10 minutes

empty rumming.

8,Vision and sound warning,and automatcally run back function.

Composition structure

1, the detection sensor (probe)

2, the circuit control system

3, the electrical machine

4. The conveyor belt

5, the rack

6, the wing housing

7, drive shaft

8. Optical Infrared emitters

9, the fixed foot

10, a control panel

Operating procedures

1) Check the machine probe, the conveyor belt, whether the debris,

tools, etc., should be removed if the following between the probe

and the surface of the conveyor belt below the window pallet.

2) Detection

3) the subject goods should not be too much, can not exceed the

detection channel, if a collision detection probe may cause false

alarms.

4) If the machine detects the abnormal sound, should immediately

stop inspection, troubleshooting and then tested.

5) detection probe should remain very stable, does not allow the

probe stack anything allowed by the probe as a rest support, press

the "Run" button to start action should be light, to prevent false

alarms due to vibration.

6) the machine to vibration or power fluctuations, and occasionally

there will be an alarm phenomenon is normal, not a fault.

7) After each test should be promptly click the "Power" button and

unplug it off.

Needle machine maintenance

1. Each test is completed, the conveyor belt response, probe

maintenance on the machine removed the foreign body. Special

attention probe window below the surface of any debris between the

pallet and the conveyor belt is not allowed.

2. Rinse detector is not allowed to remove the debris. To ensure

the conveyor belt, the probe control box dry.

3. When summer temperatures or a long time without much prior to

use shall conveyor, pallet accumulation of moisture on the

electrical box to dry before boot.

4. Regularly check the machine transmission parts refueling, if

loose fastening screws should be tightened.

5. Motor Maintenance

The picture of metal detector: