Product Details

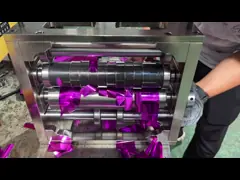

CustomizedChilling Roller

Description of Chilling Roller:

The primary purpose of a chill roll is to remove heat from the

product before any downstream operations. Several key factors are

necessary to determine the heat removal or cooling capabilities of

a roll used in extrusion operations—polymer type, maximum extruder

output, melt temperature at the die exit, desired temperature off

the roll, and specific heat of the polymer. These factors allow

calculation of the heat that a specific set of process conditions

can remove. Before making a significant process change such as

increasing total rate, heat removal rate therefore requires

consideration. Heat removal rate is one important thermal factor.

Another is coolant flow rate.

Use of Chilling Roller:

Also they are widely used for plastic, paper, textile, roofing,

laminating, winding, and extruding applications, these chilling

rollers offer high efficiency. The size and pattern are customized.

Features:

Efficient cooling capacity

Less maintenance

Dimensionally accurate

Pattern: produce roller according to the technical drawing and URS

Competitive advantage:

1) Top 5 in China for roller in China

2) World class quality for roller

3) High capacity in China, quick delivery time

4) 5 “S”for lean management; continuous improvement encourage

system

Company Profile

The company is one of subsidiary companies for "ST.KEY

INTERNATIONAL GROUP S.A". Also the company has three factories in

China: embossing roller factory in Changzhou, LED light factory in

Kunshan, ceramic sanitaryware factory in Chaozhou.

The factory of embossing roller is located in Wujin Industry Area

in Changzhou China, and have high production capacity in China. Up

to now, we have become top 5 for embossing roller manufacturer in

China due to our large production scale and leading technologies.

With premium quality, we have gained a high reputation in both

domestic and overseas markets.

We control the procurement of raw materials strictly, relying on

abundant technology, importing and taking advantage of occident

advanced production techniques and equipment, improving our product

structure continuously, and controlling product quality strictly.

We also operate based on lean management and 5S management methods.

All our products are manufactured in accordance with Chinese, EU

and USA standards. Our R&D cente develops a lot of new products

according to our customer's requirements.

We have exported to many overseas markets such as Asian, North

American, South American, European, Middle East, African, etc.

The advantages for embossing roller factory are:

- More than 25 years experiences for producing rollers

- World class quality for roller

- Top 5 for embossing roller manufacturer in China

- High capacity in China, quick delivery time

- 5 “S” for lean management; continuous improvement encourage system