Product Details

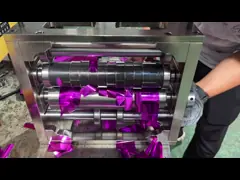

Automatic Structural , Tubing , Pipe And Plate Rollers , Beam

Bending Roll

DESCRIPTION

Yield, tensile strength, width, thickness, and diameter (or radius)

of the part all have to be considered. These properties, more than

anything else, determine the proper plate roll sizing. For example,

a higher yield or tighter diameter will require more pressure to

form.

Also, minimum and maximum width is important. Even something as

straightforward as material thickness can vary, yet still fall into

accepted plate and sheet mill tolerances. For instance, a 0.25-in.

plate can sometimes vary in thickness from 0.23 to 0.262 in.

On the application side, you need to know the minimum and maximum

diameter of the cylinders to be formed and if cones or special

shapes will be made. All of this information is integral in finding

the correct type and size of plate roll. The end goal is to achieve

parallel surfaces while producing the diameter you need.

plate roller

To serve your plate, structural, tubing, and pipe rolling needs, we

have the capabilities to meet virtually all of your steel and alloy

rolling requirements. DFI guarantees the quality and workmanship of

all our products to meet your specifications. Our rolling

capacities include:

Metal Plate Rolling

Beam Bending

Channel Bending

Angle Rolling

Square and Rectangular Tube Bending

Metal Pipe Bending

Company Profile

The company is one of subsidiary companies for "ST.KEY

INTERNATIONAL GROUP S.A". Also the company has three factories in

China: embossing roller factory in Changzhou, LED light factory in

Kunshan, ceramic sanitaryware factory in Chaozhou.

The factory of embossing roller is located in Wujin Industry Area

in Changzhou China, and have high production capacity in China. Up

to now, we have become top 5 for embossing roller manufacturer in

China due to our large production scale and leading technologies.

With premium quality, we have gained a high reputation in both

domestic and overseas markets.

We control the procurement of raw materials strictly, relying on

abundant technology, importing and taking advantage of occident

advanced production techniques and equipment, improving our product

structure continuously, and controlling product quality strictly.

We also operate based on lean management and 5S management methods.

All our products are manufactured in accordance with Chinese, EU

and USA standards. Our R&D cente develops a lot of new products

according to our customer's requirements.

We have exported to many overseas markets such as Asian, North

American, South American, European, Middle East, African, etc.

The advantages for embossing roller factory are:

- More than 25 years experiences for producing rollers

- World class quality for roller

- Top 5 for embossing roller manufacturer in China

- High capacity in China, quick delivery time

- 5 “S” for lean management; continuous improvement encourage system