Product Details

DESCRIPTION

Plate rolls have gotten seriously big. Machine pits are deeper, the

frames massive, the rolls ever larger. Certain machines have

specifications stating they can roll plate of certain yield

strengths to 4, 6, and 7, even 11 inches—cold.

According to sources, several factors are spurring demand. First is

increased demand from the sectors providing infrastructure and

power generation. Second, a lot of old iron remains in heavy fab

shops; many are upgrading, and the type of machine they're

purchasing has made such heavy rolling practical and

cost-effective: the variable-geometry plate roll.

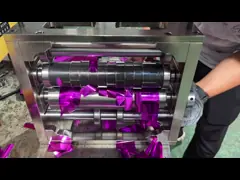

plate roller

Steel plate rolls–whether they have two or three bottom rolls–all

have a top roll. The top roll can be sized to roll plate into

cylinders or cylinder segments to radii close to the diameter of

the top roll. However, relatively small top rolls can deflect in

the center under the pressure of curving steel plate. Alternately,

larger-diameter top rolls deflect less but limit the machine to

rolling only larger diameters.

Specification of plate roller

1. Special bending techniques, high-accurate end pre-bend,

numerical control

2. Man-machine conversation, bending auto-compensation

3. PLC control, one worker operation, high efficient

Company Profile

The company is one of subsidiary companies for "ST.KEY

INTERNATIONAL GROUP S.A". Also the company has three factories in

China: embossing roller factory in Changzhou, LED light factory in

Kunshan, ceramic sanitaryware factory in Chaozhou.

The factory of embossing roller is located in Wujin Industry Area

in Changzhou China, and have high production capacity in China. Up

to now, we have become top 5 for embossing roller manufacturer in

China due to our large production scale and leading technologies.

With premium quality, we have gained a high reputation in both

domestic and overseas markets.

We control the procurement of raw materials strictly, relying on

abundant technology, importing and taking advantage of occident

advanced production techniques and equipment, improving our product

structure continuously, and controlling product quality strictly.

We also operate based on lean management and 5S management methods.

All our products are manufactured in accordance with Chinese, EU

and USA standards. Our R&D cente develops a lot of new products

according to our customer's requirements.

We have exported to many overseas markets such as Asian, North

American, South American, European, Middle East, African, etc.

The advantages for embossing roller factory are:

- More than 25 years experiences for producing rollers

- World class quality for roller

- Top 5 for embossing roller manufacturer in China

- High capacity in China, quick delivery time

- 5 “S” for lean management; continuous improvement encourage system