Add to Cart

Product Overview:

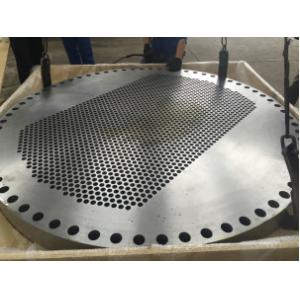

Shell and tube heat exchangers consist of a cylindrical shell with a bundle of tubes inside it. They work by circulating a hot liquid inside the shell around the tubes, which contain a cooler liquid.

In a fixed tube sheet heat exchanger, the tubes are permanently positioned inside the shell and thus are not removable. In a multi-pass heat exchanger, the liquid passes through the tube bundle two or more times.

DAC Worldwide’s Multi-Pass Fixed Tube Sheet Heat Exchanger Training Model (286) is a highly-detailed scale model that teaches learners about the operation and maintenance of industrial multi-pass fixed tube sheet heat exchangers.

An accurate, to-scale replica of a typical industrial heat exchanger, the model features a clear acrylic shell and can be completely disassembled. It reflects design standards established by both the Tubular Exchanger Manufacturers Association (TEMA) and the American Society of Mechanical Engineers (ASME).

Features & Specifications

Product Pictures:

Company Introduction:

Packing and Delivery:

Quality Control:

1. Incoming Raw Material Inspection

2. Raw Material Segregation to avoid steel grade mix-up

3. Heating and Hammering End for Cold Drawing

4. Cold Drawing and Cold Rolling, on line inspection

5. Heat Treatment, +A, +SRA, +LC, +N, Q+T

6. Straightening-Cutting to specified length-Finished Measuring

Inspection

7. Machanical Testing in own labs with Tensile Strength, Yield

Strength, Elongation, Hardness, Impact, Mictrostruture etc

8. Packing and Stocking.

FAQ:

A: A professional steel pipes materials inventor, manufacturer and solution provider

A: Generally it is 7-14 days if the goods are in stock. or it is 30-60 days if the goods are not in stock, it is according to quantity.

A: Yes, we could offer the sample for free charge but need pay the cost of freight.

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30%

T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us

ASTM B265 Hot Rolled Titanium Plates TA1 Plate Heat Exchanger Sheet