Who We are ?

-------A professional steel pipes materials inventor, manufacturer

and solution provider

Torich International Limited is a professional manufacturer and

exporter of steel pipes materials. It is an international marketing

and sales company specialized in steel tubes, which holds the

factories of Seamless Steel Tubes with Carbon and Alloy Steel

Grade, Welded Precision Steel Tubes,DOM Steel Tubes, Seamless &

Welded Stainless Steel Tubes with Nickel and Alloy Steel Grade.

Our factory was established since 1997, with the name of TORICH

INTERNATIONAL LIMITED. The factories’ technicians are of great

engineering experience in steel pipe industry for more than 20

years, which are in great command of production technology for Cold

Drawing and Cold Rolling. So we have strong technician team and

manufacturing capability.

What products we do?

------- Invent and produce various Precision Steel Pipes

Our steel pipes cover the following ranges:

Seamless Precision Steel Pipes

Bearing Steel Tubes

Welded Precision Steel Pipes, with DOM production

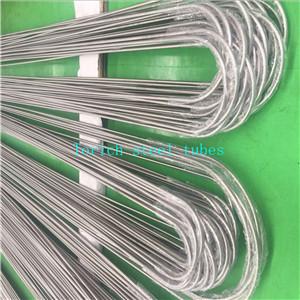

Seamless Heat Exchanger Steel Pipe

Seamless Boiler Steel Pipes

Honed Tubes

Hydraulic Cylinder Steel Tubes

Hydraulic Telescopic Cylinder Tubes

Seamless Structural Steel Pipes

Seamless Mechanical Steel Pipes

Seamless Alloy Steel Tubes & Pipes

Seamless Stainless Steel tubes

Welded Stainless Steel Tubes

Seamless Stainless Steel Tubes & Pipes

Welded Stainless Steel Tubes & Pipes

Seamless Carbon Steel Tubes & Pipes

Nickel Alloy Steel Tubes & Pipes

What TORICH do:

1. Producing Steel Tubes

2. Selling both on Domestic and International Market

3. Precisely Targeting Customers’ Requirement- Sourcing the right

factory for right products for Customers

Products Application:

Oil Cylinders

Air Cylinder,

Automotive Cylinder Liners

Boilers, Pressure Vessels

Shell & Heat Exchangers

Jack Lifting

Telescopic Systems

Pneumatic Cylinders

Agricultural Machineries

Size range is:

O.D. 4-350mm,

W.T. 0.5-30mm,

Length: according to customer’s requirement and agreement

Steel Grade:

Carbon Steel Grade:

ST35.8, ST37.0, ST44, ST52;

E155, E195, E215, E235, E275, E355;

195GH, P235GH, P265GH, P195TR1, P195TR2, P235TR1, P235TR2, P265TR1,

P265TR2;

SAE1010, SAE1020, SAE1026, SAE1035, SAE1045;

Carbon steel tube: SA178, A179, A192, A210, SA213, SA214, etc.

Alloy Steel Grade:

T2, T5, T9, T11, T12, T17, T21, T22, T91,T92, 15Mo3,16Mo3,

13CrMo44;

SAE4130, SAE4140, 40Cr, 40Cr4, 10CrMo910, 12CrMo910, 11CrMo910,

25CrMo4, 35CrMo, 35CrMo4, 42CrMo4, 34CrMo4, 20MnV, 20MnV6,20CrMn;

Carbon steel tube: A179,A192,A210,DIN17175,etc.

Bearing Steel Grades:

GCr15 52100 suj2 suj3 100Cr6 SKF3S SKF3S 20CrNiMo 8620H 4118H;

Nickel Alloy Grade:

N02200/2201, N04400, N06600, N06601, N06625, N06852, N06219,

N06690, N08800/8810/8811, N08825, N08028, N08535, N08904, N08925,

N08926, N010276, N06022, etc.

Austenitic/Super Austenitic Stainless Steel Grade:

304/304L, 316/316L, 314, 321, 347H, 316Ti, 316LMod, 317L/N, 310S,

253MA, 330, 904L, S31254, XM-19, etc.

Ferrite/Martensite Stainless Steel Grade:

TP410, TP405, TP420, TP430, TP430Ti, TP403, TP409, TP444, TP439,

TP446, etc.

Duplex/Super Duplex Stainless Steel Grade:

S31803, S32304, S31500, S32550, S32750, S32760, etc.

Corporate Culture:

We focus on Quality First, Quality Traceability, and Quality

Stability!

We focus on Customer First, People First, and Quality-Oriented!

Success:

First factory started in 1997, in the name of Torich , now covers

50000 square meters of factory building, with more than

100employees, and over 45 million RBM assets.

In 2008, we started the company of Torich International Limited for

international business and marketing.

Welcome partners from all over the world for long term cooperation!