Add to Cart

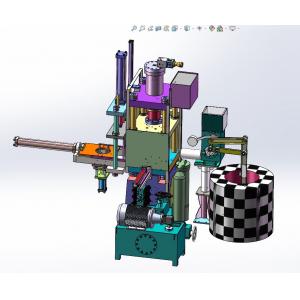

125T Aluminum Die Casting Machine Press Submersible Motor Rotors With 4 Cavity Die

supply power press machine,hydraulic press, press machine,bending machine

die casting press machine for motor rotors feature:

This amuminum die cast machine is a three-beam and four-column structure, and the machine has the functions

of feeding& back mold,fast closing mold, slow closing mold, build pressure, slow die casting, fast die casting,

open the mold, take off the low mold, ejector false shaft, ejector rotor and so on.

According to the production process requirements. Equipment electrical operation is equipped with Inch, manual,

semi-automatic three process selection mode, the selection of "inch mode" function is mainly used for the adjustment

of the machine. The manual function is whether each action is normal after adjustment. "Semi-automatic" means that

the die-casting process can be completed only by closing the protective door.

The closing mold using filling liquid fast mold, fast contact with the mold and convert to slow speed, it can more

effectively increase the working efficiency. It will not cause the damage to the mold.

The front and rear safety doors of this machine adopt the pneumatic push & pull device, and the electrical interlock,

it will go to the next step procedure until the protection doors are closed.

The Working principle process for die casting machine with 4 cavity

die:

The process program of 4 rotor cavity die one times: manual place

the work piece→ feeding mold→

pushing low mold to top→ Give aluminum liquid by hand or by the robot arm for ladle→ pushing low mold to

discharge pressure

→Pneumatic door close→ Quick closing mold→ slow speed close→ die casting→ fast pressing→ Cooling delay→

die casting device slowly retreat→ break the mold→ open the protection door → second pushing low mold to top→

Die-cast cylinder push excess aluminum cake→ Take the excess aluminum cakes manually

→ second pushing low mold to down→ Stop from retreat mold to push false shaft→ ejector false shaft go down→

ejector false shaft return→ Stop from the mold retreat to the ejector rotor position→ ejector rotor rod go up→

manual take away the rotor→ ejector rotor rod return→ pressure shooting device return→ Go to the next work cycle

motor rotors die cating press machine Technical Data

| TECHNICAL FEATURES | |||

| 1 | Type | four column Hydraulic press | |

| 2 | mold clamping force | 1250KN(125T) | |

| 3 | Pressure of fluid | 25.8Mpa | |

| 4 | The Max. distance between worktable and slipper | 1000 mm | |

| 7 | The Max. stroke of the slipper | 500mm | |

| 8 | press shoot force | 1250KN | |

| 9 | Dimension of worktable | 1100X900mm | |

| 13 | feeding mold force | 200KN | |

| 14 | fedding mold distance | 900mm | |

| 15 | ejector force | 250KN | |

| 16 | ejector stroke | 100mm | |

| 17 | The diameter of hydraulic cylinder | 220mm | |

| 18 | The diameter of the center of plunger bar | 40mm | |

| 19 | The depth of the center of plunger bar | 65mm | |

| 20 | The screw thread diameter of plunger bar | 150mm | |

| 21 | Motor Power | 22KW | |

| 22 | Overall sizes(mm) LxWxH | 1500x3100x3300 | |

| 23 | Weight | 7500kg(N.W) | |

| 26 | Delivery date | 30days after receive down payment | |

Packing & shipping

PVC film covered hydraulic press

Whole machine fixed in the container with steel rope,very safe

Wooden case or pallet or iron box

If have stock,can provide right now

If no stock,small machine delivery time 7-15days.Big machine delivery time 25-40days.

Can give destination port best price or cost to the customer factory

Guarantee & After Sale Service

Guarantee for 2 year exluding comsumable parts .Extra fee is paid if out of date.

Any damage to the machine caused by improper use will be charged.

when receiving the your money, we will prepare machine for you,it

will spend 15-30days,

to get the shipping pictures for you.

24-hour technical support Internet or by Telephone, free

instructions and

Problem solving.

Free installation and fully test before sending and free training

for operators

finished motor rotors on the die cating press machine