Add to Cart

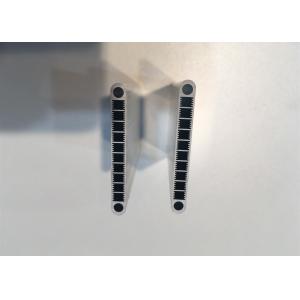

Alloy 3003 / 3102 Automobile Flat Aluminium Condenser Tube Extrusion

Product Introduction:

Micro-multiport extrusion aluminum tube (MPE tube) is mainly used for the production of heat exchangers. Due to its high corrosion-resistance & good heat conductivity, MPE tube is particularly well suited for the use in evaporators & condensers. MPE tube is required increased burst strength and better heat conductivity for an optimized product size. To meet the market requirement, we developed zinc-coated & flux coated MPE tubes, it can be supplied in the form of coils, or fixed length by non-cutting separation method.

The Micro-multiport extrusion aluminum tube (MPE tube) is unique

tubes developed with the highest manufacturing quality,we are

trying our best ability to create the low weight design to help our

customers to decrease the tube weight and also decrease the

production cost,in the meantime,to make sure that the tube thermal and electricity conductivity is keeping on good,and the

tube we are supplying is having very good forming and bending

capability,and also good corrosion and pressure resistance which

could make our customers' products keep a long life and good

working performance.Besides,aluminum is a very eco-friendly

material which is having very good recycling value.For the tube size,we are having very strict mould

which could control the tolerance within a very narrow range.For

the tube inside and outside,it can be supplied clean,no block,and

no impurity.

| Alloy: | 3003,3102,1100,1050 | Temper: | O,F,H111,H112 |

|---|---|---|---|

| Shape: | Flat Oval | Applications: | Radiators,Condensers,Evaporators |

| Surface: | Zinc-spraying / Without Zinc-spraying |

Commonly used material chemical composition:

| No. | Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | V | Ti |

| 1 | 1050 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | --- | ≤0.05 | ≤0.05 | ≤0.03 |

| 2 | 1100 | ≤0.95(Si+Fe) | 0.05-0.20 | ≤0.05 | --- | --- | ≤0.10 | --- | --- | |

| 3 | 3102 | ≤0.40 | ≤0.70 | ≤0.10 | 0.05-0.40 | --- | --- | ≤0.30 | --- | ≤0.10 |

| 4 | 3003 | ≤0.15 | ≤0.15 | ≤0.01 | 0.90-1.10 | ≤0.03 | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

| Alloy | Temper | Tensile Strength | Yield Strength | Elongation |

| 1050 | O/F/H111/H112 | ≥65MPa | ≥20MPa | ≥25% |

| 1100 | O/F/H111/H112 | ≥75MPa | ≥20MPa | ≥25% |

| 3102 | O/F/H111/H112 | ≥75MPa | ≥20MPa | ≥25% |

| 3003 | O/F/H111/H112 | ≥75MPa | ≥20MPa | ≥25% |

| Range | 0~3 | 3~6 | 6~30 | 30-120 | 120-315 | 315-1000 |

| Tolerance | 0.05 | 0.1 | 0.15 | 0.2 | 0.3 | 0.4 |

Applications:

Our aluminium tubes are widely used for automobile condensers and evaporators for air conditioning systems as well as liquid lines for air conditioning, heater cores and radiators for engine cooling systems, charge air coolers and other cooling systems.

Our Extrusion equipment review:

1)Surface stains and foreign body removal

2)Oxide aluminum rod surface removal

3)Eddy current inspection: It uses the equipment of Germany DB company,which can detect,identify and sort the defects of flat pipe holes and broken ribs.

4)Zinc spraying system: It uses the thermal spraying equipment of Japanese kucan company,which has a system of automatic adjustment based on speed.The surface is uniform and delicate,to make the demands of 6+/-2g,8+/-2g come true.

Package: In coil or Straight with fixed length.Packed in plywood

box specialized for export.

Surface Treatment : With Zinc spraying or without Zinc spraying.