waste tire recycling

Brand Name:United Tech

Certification:www.utshredder.com

Model Number:tyre recycling

Minimum Order Quantity:1 SET

Payment Terms:www.utshredder.com

Place of Origin:China

Contact Now

Add to Cart

Active Member

Location:

Zibo Shandong China

Address:

New Era Business Center, No. 145 Zhengtong Road, Zibo City, Shandong Province, China

Supplier`s last login times:

within 14 hours

Shipping

lt's easy to get a shipping quote! Just click the button below and complete the short form.

Get Shipping Quote

Product Details

Company Profile

Product Details

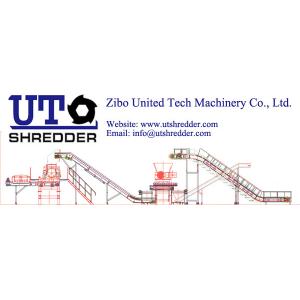

The used tire recycling system are designed for recycling car and

truck tires for the production of clean rubber crumb and separation

of steel and textile.

Using normal temperature and non-chemical processing technology,

these recycling systems are cost effective and don’t create

secondary pollution. This system is intended for customers who

require an entry level, small scale tire recycling system.

According to different tire and requirements, the production line

may including as follows,

1. Automatic de-beader: removal of the reinforcing steel wires from

the tire rims 60pcs/h;

2. Conveying system: convey or belt, crew conveyor and air

transportation system;

3. Shredder: shears the tires into 50-150mm strips

4. Rasper: reduces the shred into 15-20mm chips and liberates

remaining steel from the rubber;

5. Over-belt magnet: separation of liberated steel from the rubber

chips 98%;

6. Granulator: size reduction of the chips to 1-4mm granules and

liberates the textile fraction to allow separation;

7. Vibratory screen: sorts the granules by size and removes the

majority of textile;

8. Zig-zag classifier: removal of remaining textile;

9. Drum magnet: removal of remaining steel fines;

10. Grinder: size reduction of the granules to 30-100mesh grinds;

11. Automatic big-bag station: storing or packing of finished

production.

Features:

1.Integral tire feeding, no pre-shredding or wire de-beading

demanded;

2.All-in-one processing: from tires to granules, production to

poackaging - no secondary handling process;

3.Maximum through put up to 5000kgs/h, with no more than 7 opeators

demanded;

4.Multiple options of machinery models to meet diverse requirements

of capacity, 200kgs/h - 5000kgs/h;

5.Full assemble two-floor infrastructure makes assembly and

maintenance easier and safer;

6.Seamless assembly joints enable perfect control of dust and

smoke;

7.800-100 hour “ real world” testing on principal machines ensures

stable performance;

8.CE certification: uniform standard and fine workmanship.

Testing:

Prior to delivery from our factory, all equipments and machineries

are set up and tested under “real world” conditions to ensure the

plant capacity and quality of the finished products are guaranteed.

Customers are welcomed and encouraged to attention these trials to

see their plant in operation, receive training on the operation and

maintenance of their system, and to see similar equipment in build.

waste tire recycling

Inquiry Cart

0