Add to Cart

1-5/8" X 1-5/8" 12 Gauge Metal Framing Strut Slotted Channel Roll

Forming Machine C Channel Making Machine

1. Solar Strut Channel Technical Parameter

1.1 Suitable Plate Material: thickness 1.5mm-2.5mm, Galvanized

steel

1.2. Working Speed: 0-20meters /min adjustable

1.3. Forming Steps: about 22 stations

1.4. Material of Roller: Cr12mov, Quench HRC58-62 Plated Chrome

1.5. Material of Shaft: 45# Advanced Steel (Diameter: 90mm),

thermal refining

1. 6. Driven system: Gearbox driven

1.7. Main Power with reducer: 18.5KW WH Chinese Famous

1.8 Power Supplier: 380V, 50 Hz, 3Phase

1.9. The whole machine is controlled by industry computer-PLC.

2. Solar Strut Channel Machine Components

| S.N | Equipment name | Quantity |

| 1 | 3T passive un-coiler | 1 set |

| 2 | Levelling device | 1 set |

| 3 | Press punching machine to make the slotted hole | 1 unit |

| 4 | Main roll forming machine | 1 set |

| 5 | Hydraulic servo following cutting | 1 set |

| 6 | control box | 1 set |

| 7 | Out tables | 2 units |

| 8 | Spare parts | 1 package |

| 9 | Safety cover | 1 set |

3.Profile Drawing

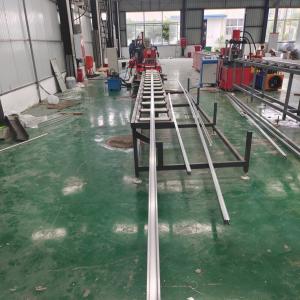

4.Machine Layout

3T automatic decoiler→servo feeding→punching machine with

mould→main roll forming machine→tracking hydraulic cutting→out put

table

5. Solar Strut Channel Application

PV support bracket Roll Forming Machine is a solar mounting support cold roll formed steel Channel that used as solar panel support or constructions for structural.

The channel is formed from metal coil strips, and then roll formed by struct channel roll forming machine into an open channel section with lips to provide additional stiffness.

The machine is able to produce 2 or 3 or more types of strut

channel by adjust the roll forming mould.The standard strut channel sizes are: 41*41, 41*21, and also some

customized shapes.

6. Our Services

Warranty: One year ,and we will provide the technical support for

the whole life.some spare parts are available.

1. As the factory, we will recommend the right profile machine to

customer, and give the professional advice.

2. Confirm the final decision during the discussion.

3. The sale person will give customer updates for each period

during the production process.

4. We finish the machine within the confirmed date, and shipping

the goods to customers safely and faster.

5. Provide the right documents to customers.

6. Give the tips(include photos, videos and manual) for

installation and operation.

7. If the buyer can not make the installation or machine appeared

the problems, if possible, we will arrange our engineer to debug

within one week. The charge for technician include the visa, round

tickers, food, accommodation and USD100/person/day for salary.