Cutting Blade Material Cr12 CZ Purlin Interchangeable Roll Forming Machine Chain Drive

Add to Cart

Automatic C Type Purlin Roll Forming Machine

Technical Parameter

Items | Specifications | |

| Material | Galvanized steel |

Un Coiler | 3T passive uncoiler | |

| Roll Forming Speed | 12--15 m/min |

Roller Stations | 20 stations | |

Roller Material | Gcr15 coated with chrome | |

Maim Motor Power | 11kw | |

Motor cutting Power | 5.5kw | |

| Material Of Cutting | CR12mov with quench treatment |

Hardness | HRC58-62 | |

Tolerance | +-1.5mm | |

Cutting blades | 3 sets | |

Electrical control system | Electric Source | 380V, 50HZ,3 phase |

Control System | PLC (Panasonic) as list in the note | |

Weight | 12 tons | |

Way Of Drive | 1.5 inch double chain |

Machine List

3 ton passive

de-coiler----------------------------------------------- 1 set

Feeding with

guide---------------------------------------------------- 1 set

Main roll forming

machine-------------------------------------------- 1 set

PLC Control

box-------------------------------------------------------- 1 unit

Hydraulic

station-------------------------------------------------------- 1

unit

Stop cutting

device----------------------------------------------------- 1 unit

Safety

cover-------------------------------------------------------------

1 unit

Out

table------------------------------------------------------------------

2 units

Advantage of Machine

1. Reasonable Price

2. High Quality

3. 12 Months Warranty

4. More Than 10 Years Experience

5. Durable

6. Reliable

During the warranty period, maintain and change the spare parts for

the customers for free (except for the instrument damage caused by

human factors or natural disasters. ) And provide technical support

for life-long.

We can design and manufacture the machine according to clients'

request! Our machines have passed CE, Guaranteed quality. Please

send us the enquiry with Profile Drawing.

Working Flow of Roll Forming Machine

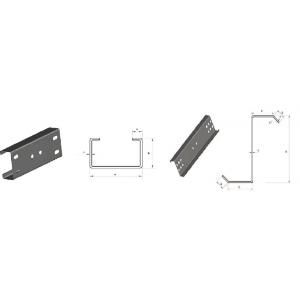

Profile of product

Photo Gallery

After-sale Serive

- The seller take responsibility to installation and commissioning

of the equipment and free training. After machine arrive the

destination, by the request of the buyer , the seller will provide

1 technical engineer to guide installation and training , and the

buyer should give the technical person with full cooperated.

- Installation period: about 5 days after the complete preparation

by the buyer such as the foundation and all necessary accessories.

- Training time: 5 days.

- Before departure of the engineers from seller, the buyer should

pay for installation and commissioning fee 100$/day to the point

account of the seller. The two-way ticket,visa, food, hotel , the

translator and insurance are all should provide by buyer with full

responsibility.

-The seller supply technical data (including forming mould drawing,

electrical elements drawing and equipment drawing etc.)