Product Details

Structure

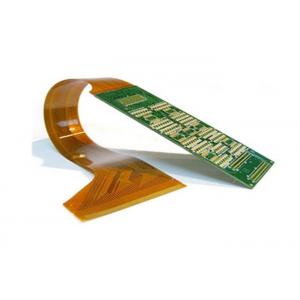

Double-Sided Rigid Flex PCB

Combination Mode

Adhesive Flexible Plate

Conductive Adhesive

Anisotropic Conductive Adhesive

Flame Retardant Properties

V0

Processing Technology

Delay Pressure Foil

Insulation Materials

Epoxy Resin

Transport Package

Vacuum Packing

What is a Rigid Flex PCB?

Printed Circuits Rigid Flex PCBA rigid flex printed circuit board

(PCB) is a hybrid circuit board design that integrates elements

from both hardboard and flexible circuits. Rigid flex PCBs are

rigid at some points on the board and flexible at others. Because

of this, rigid flex circuits can be folded or continuously flexed

while maintaining the shape of areas that need extra support. The

circuits are typically multi-layered and are comprised of flexible

circuit substrates joined with rigid boards. The flexible layers

are buried internally and completely penetrate the rigid sections

of the PCB.

One of the key benefits of a rigid flex PCB is its slim profile.

The standard dielectric in flexible circuits is .001 – .002”,

making it a great choice for ultra thin—and ultra light—packaging

needs. Adhesiveless laminates, HDI, and thin copper layers make it

ideal for fine line technology, giving you the smallest, thinnest,

and lightest solution for your circuit designs.

The proper application of Rigid-Flex circuit boards offers optimum

solutions for difficult, limited space conditions. This technology

offers the possibility of a secure connection of device components

with the assurance of polarity and contact stability, as well as a

reduction in plug and connector components.

Additional advantages of Rigid-Flex circuit boards are dynamic and

mechanical stability, the resulting 3-dimensional freedom of

design, simplified installation, space savings, and maintenance of

uniform electrical characteristics.

Use of Rigid-Flex circuit boards can reduce the total cost of the

final product.

PCB/PCBA Product Specification:

Surface processing | Lead- Free HASL/Plating gold / immersion gold /Plating gold

finger/OSP |

Layers | 1~24 layers |

Copper Thickness | 0.5OZ~1 OZ |

Board Thickness | 0.2mm~3.2mm |

Min Hole Size | 0.2mm |

Min Line Width | 0.1mm |

Min Line Spacing | 0.1mm |

Max board Size | Depends on customer’s requirements |

Solder mask type | Green/ Black/ Red/ Yellow/ White/Blue... |

Silk legend color | White / Yellow/ Black |

Data file format | GERBER file and corresponding drilling file, PROTEL series,BOM list |

Base material | FR4,aluminum based board,High TG board, Rogers,Taconic,F4B,Arlon |

Certifications | ISO9001:2000 ; TS16949; ROHS; SGS; |

PCB Assembly | DIP, SMD |

While they come at a higher cost, rigid flex boards are extremely

versatile and can be tailored to applications across a wide range

of industries. They are highly suitable for military, aerospace,

and medical devices, but they can also be implemented towards

certain commercial products.

There are several circumstances that make rigid flex PCBs as an

optimal solution. In such situations, these boards are not only

worth the investment, but also may be the most cost-effective

choice. These include:

High-shock and high-vibration environments. Rigid flex PCBs are

highly shock resistant and can survive in high-stress environments

that would otherwise cause equipment failure.

High-precision applications where reliability is more important

than cost considerations. In situations where a cable or connector

failure would be dangerous, the more durable rigid flex PCBs are

preferable.

High-density applications.Some assemblies lack the requisite

surface area for all the necessary connectors and cables. A rigid

flex circuit can economize space to solve this problem.

Applications requiring multiple rigid boards. When assemblies get

crowded with more than four connected boards, it may be optimal and

more cost effective to replace them with a single rigid flex PCB.

More broadly, rigid flex PCBs have the following advantages:

Survive high levels of shock and vibration

Survive hundreds of thousands of flex cycles

Reduce package weight

Increase circuit density

Decrease necessary assembly operations

Rigid flex circuit assemblies are ideal for reducing and/or

eliminating connectors, as well as the labor, yield, transmission,

and reliability issues that are inherent in their application. Any

assembly that can benefit from these features can benefit from a

rigid flex PCB.

A Rigid-Flex PCB is a hybrid board that consists of a combination

of rigid and flexible printed circuit boards. These boards are

designed by combining flexible circuit boards with one or more

rigid boards.

The flexible part of the board is usually used for providing

interconnections between rigid boards, which allows narrow

conductor lines which take up less space making the boards smaller.

Using flexible PCBs for interconnections also eliminates the need

for connectors, which are bulky and heavy making rigid-flex printed

circuit boards much lighter. Interconnections using flexible PCBs

over connectors also provide lower losses and accommodate

controlled impedance and eliminate connection problems such as cold

joints.

Another major advantage of Rigid-Flex boards is the use of

different substrate materials in different sections on the board.

Some sections of the board might require high performance

substrates which are expensive while others sections might not

could use a standard FR-4 substrate. This flexibility in terms of

substrate selection can optimize the performance and cost of

Rigid-Flex PCBs.

Designers often use Rigid-Flex PCBs as they provide a lot of design

flexibility. These boards are also more cost effective than

flexible PCB boards.

Company Profile

Xinchenger Electronics co.,Ltd established in 2009,we have committed ourselves to manufacturing

various of printed circuit boards.

We have accumulated abundant experiences in the line of high

frequency microwave business for which widely apply to power

divider,combiner,power amplifier,line amplifier,base station,RF

antena,4G antena so on and so forth. Our company's sufficient

stocks of hi-frequency pcb materials such as

Rogers,TACONIC,Arlon,Isola,F4B,TP-2,FR-4 (dielectric rage:2.2-16)

mainly used in the area of high technologies like communication

device,Electronics,Aerospace,Military industry to meet our

worldwide customers with high quality. Furthermore,we also keen on

helping customers shorten the period of production development and

24 hours of sample service is available.

Since the day of company foundation we continuously engaged in

researching special and high precision printed circuit boards with

the strong production capability of 2 to 28 layers of highly

precise impedence,multi-layer blind buried,multi-layer

mix-compression,high TG, copper substrate,Ceramic substrate PCB. We

emphasize the significance of traning program for every single

staff in the company even grass-roots employees which becomes the

most competitive factors to excel from others,our company have many

experienced and professional teams from management to production

line,30% are highly educated among the total amount of

employees,advanced engineers and senior technicians are up to 80

people.

With advanced foreign technology supports and domestic 3G/4G device

manufacturer in microwave pcb field which lead our experienced

hi-frequency researching team to one step ahead of the line of

printed circuit board business,we are honored to obtain sound

reputations over our worldwide customers on the basis of fine

qulity,prompt delivery,satisfied after sales service for may years

and we assure our customers that we will return the favors with

more and more superior products in the near future.