Add to Cart

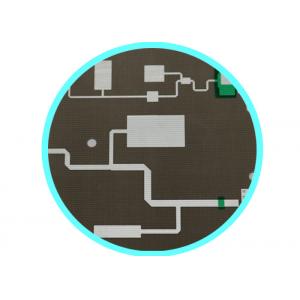

PCB Audio Amplifier RF Transceiver Taconic High Frequency PCB

Double Layer 1oz Electronic Circuit

Quick detail:

| Origin:China | Special: Taconic material |

| Layer:4 | Thickness:0.79mm |

| Surface: ENIG | Hole:0.8 |

Specification:

PCB Audio Amplifier RF Transceiver Taconic High Frequency PCB

Double Layer 1oz Electronic Circuit TACONIC high-performance

insulating material for microwave, radio frequency (RF) and

high-speed digital signal processing (DSP) market with PTFE/type

woven glass fiber fabric sheet.This material can be applied to LNAs

LNBs, PCS/PCN antenna system, global positioning system (GPS) and

UMTS antenna system,And the power amplifier, passive components,

collision avoidance radar system, aviation help guide remote

control technology and system of the phased array radar.

Taconic materials are UL 94V-0 rated for active devices and high

power RF designs.

High Speed Design Frequency PCB Board Special high electromagnetic frequency circuit boards, in general,

can be defined as the frequency of the high frequency of 1GHz. Its

physical properties, precision, technical parameters required is

very high, commonly used in automotive anti-collision systems,

satellite systems, radio systems, etc.

The basic characteristics of a high frequency board material

requirements are the following:

(1) dielectric constant (Dk) must be small and very stable, usually

the smaller the better signal transfer rate and the dielectric

constant of the material

Inversely proportional to the square root of high dielectric

constant is likely to cause the signal propagation delay.

(2) the dielectric loss (Df) must be small, mainly affect the

quality, the smaller the dielectric loss signal transmission of the

signal loss is smaller.

(3) as far as possible consistent with the coefficient of thermal

expansion of the copper foil, copper foil separated because of

inconsistency will cause changes in the hot and cold.

(4) to low water absorption, high water absorption will affect the

dielectric constant and dielectric loss when damp.

(5) Other heat resistance, chemical resistance, impact strength,

peel strength, etc. must also be good.

Typical Applications

Microwave Antenna 4 Layer PCB Board,Radio frequency (RF) and microwave PCB’s are a type of PCB designed

to operate on signals in the megahertz to gigahertz frequency

ranges (medium frequency to extremely high frequency). These

frequency ranges are used for communication signals in everything

from cellphones to military radars. The materials used to construct

these PCB’s are advanced composites with very specific

characteristics for dielectric constant (Er), loss tangent, and CTE

(co-efficient of thermal expansion).

High frequency circuit materials with a low stable Er and loss

tangent allow for high speed signals to travel through the PCB with

less impedance than standard FR-4 PCB materials. These materials

can be mixed in the same Stack-Up for optimal performance and

economics.

Parameter:

| o | Item | Data |

| 1 | Layer: | 1 to 24 layers |

| 2 | Material type: | FR-4, CEM-1, CEM-3, High TG, FR4 Halogen Free, Rogers |

| 3 | Board thickness: | 0.20mm to 3.4mm |

| 4 | Copper thickness: | 0.5 OZ to 4 OZ |

| 5 | Copper thickness in hole: | >25.0 um (>1mil) |

| 6 | Max. Board Size: | (580mm×1200mm) |

| 7 | Min. Drilled Hole Size: | 4mil(0.1mm) |

| 8 | Min. Line Width: | 3mil (0.075mm) |

| 9 | Min. Line Spacing: | 3mil (0.075mm) |

| 10 | Surface finishing: | HASL / HASL lead free, HAL, Chemical tin, Chemical Gold, Immersion Silver/Gold, OSP, Gold plating |

| 11 | Solder Mask Color: | Green/Yellow/Black/White/Red/Blue |

| 12 | Shape tolerance: | ±0.13 |

| 13 | Hole tolerance: | PTH: ±0.076 NPTH: ±0.05 |

| 14 | Package: | Inner packing: Vacuum packing / Plastic bag,Outer packing: Standard carton packing |

| 15 | Certificate: | UL,SGS,ISO 9001:2008 |

| 16 | Special requirements: | Buried and blind vias+controlled impedance +BGA |

| 17 | Profiling: | Punching, Routing, V-CUT, Beveling |