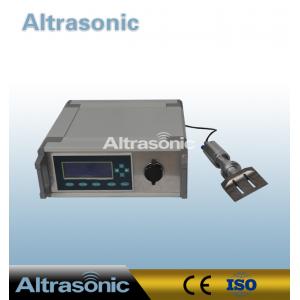

Titanium Blade 40khz Ultrasonic Cutting Machine , Ultrasonic Cutting Equipment

Add to Cart

Titanium Blade 40khz Ultrasonic Cutting Equipment

Description:

Ultrasonic cutting machine is an ultrasonic device specially used

for cutting, which is one of the important categories of ultrasonic

applications.

The principle is completely different from traditional cutting. The

ultrasonic cutting machine utilizes the energy of the ultrasonic

wave to melt the local heating of the material to be cut, thereby

achieving the purpose of cutting the material.

The difference between traditional cutting and ultrasonic cutting:

Ultrasonic cutting machine is the use of wave energy for cutting

equipment, the main t feature is not to use the traditional edge.

The traditional cutting utilizes a tool with a sharp edge to press

the cutting material. The pressure is concentrated at the edge of

the blade, the pressure is very large, more than the shear strength

of the cutting material , then the material is cut open. As the

material is cut by a strong pressure, so the cutting tool edge

should be very sharp and the material itself has to bear the

relatively large pressure. Therefore the cutting effect for the

soft, flexible material is not good, especially more difficult for

sticky material.

Specification:

| Frequency | 40Khz |

| Power | 500W- 800W |

| Input | AC110-240V, 50/60Hz |

| Power Controller | stepping or continuous |

| Material Of Cutting Head | aluminum alloy, stainless steel, titanium alloy, alloy steel. |

| Machine Wight | 4 kg-16KG |

| Accessories | foot switch, additional blade |

| Cooling Device | compressed air mouth can be installed. |

| Cable Length | 2M or customized |

| Foot Switch | available |

Applications:

Rubber tire and its related products

Advantages:

Produces a fusion effect for neat cuts, especially in viscous materials

Can be used for many different types of materials

Creates finely finished and structured objects

Emits less heat compared to other industrial cutting methods

Vibration enables various shapes for cutting holes.