Add to Cart

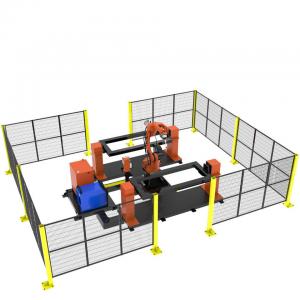

HWASHI 6 Axis CO2 MIG MAG TIG Industrial Automatic Welding Robot, welding robot arm

1. Welding system: Panasonic MIG or TIG welding machine with

automatic wire feeding system. Stable performance.

2. Automatic alarm system: if any problem on the wire feeding or

gas supply and so on, the welding robot will alarm and the

welding will stop until you clear the alarm.

3. Welding gun system: famous brand TBI welding gun.

4. Welding gun cleaning and wire cutting system: TBI brand.

5. Working station positioner: It is designed with two sets of

working table. Single table could achieve 3600 rotation which is

suitable for multi-angle welding. Two sets of positioner system

could achieve 180°rotation through spindle motor. It could achieve

alternative use so as to increase efficiency.

6. Work piece clamping system: the cylinders will push and clamp

the work piece. Balanced and stable clamping force.

7. Arc light baffle: cylinder pushes automatic rotation. Use for preventing light pollution during working process. 8. Start control panel system: Manual/Automatic button platform with portable structure. Convenient for operation.

USED FOR LOCATING THE WORK PIECE ONTO THE AUTOMATIC ROTATE TABLE

Guangdong Hwashi Technology Inc. was established in 2001. The

headquarter is located in Hwashi industrial park in Huizhou. Hwashi

is a high-tech enterprise specialized in developing, manufacturing

and selling of resistance welding machine, automatic welding

machine and an industrial robot.

In the past 20 years, Hwashi has obtained more than 50 patents for

invention patents, utility model patents, design patents, and

software Copyrights. It is the drafting unit of several national

standards and industry standards. Hwashi has been awarded "China

famous brand", "Guangdong famous brand", "China quality credit

enterprise", "world outstanding Chinese businessman association

member unit", "Guangdong province science and technology innovation

quality management advanced unit", "Guangdong province academician

expert enterprise workstation" and many other honorary titles.

For 20 years, Hwashi keeps innovating and follow up with the latest

technology in the world. Invest heavily in product development and

innovation every year. In cooperation with key universities and

national key laboratories and engineering technology centers in new

materials and processes, the "medium frequency inverter" technology

was first introduced into resistance welding equipment. Help to

realize the "unmanned, intelligent" factory, the practice we have

been striving for is to create efficient, energy saving, safe and

environmentally friendly production environment for customers.

With the trend of intelligent manufacturing in the world, Hwashi

has set up a large-scale robot development base of 50,000 square

meters in Yichun City, Jiangxi province. Introducing the world's

top advanced production and processing equipment in our factory. We

have a technical team and high-quality workers including

mechanical, electronic, welding, automatic control,

electromechanical integration, and management. We are committed to

providing customers with efficient automation welding solutions in

order to become a leading enterprise in world-class industrial

intelligent equipment.