Add to Cart

Modern industrial equipment process request centrifugal pump are

basically work under condition of variable flow. An automatic

recirculation valve (ARC valve) is a multifunctional valve whose

primary purpose is to ensure that a pre-determined minimum flow is

assured through a centrifugal pump at all times. This is important

as centrifugal pumps

suffer from overheating and cavitation and can be permanently

damaged if they run dry.

Through many years of research and development, continuous

innovation and practice, shanghai datian valve Co. research ZD

series Automatic recirculation control Valve, to prevent

overheating, serious noise, unstable and erosion damage of

centrifugal pump under low load operation. As long as the flow rate

of the pump valve

below a certain value, the bypass backflow mouth will automatically

open to ensure necessary minimum flow of pump.

If you use centrifugal pumps for any liquid-boiler feed water,

condensate, or process fluids, a significant investment has been

made in the pump, driver and related controls. Minimum flow

protection is vital upon

pump start up and low demand conditions. If reliable protection

does not exist, the following unfavorable effects can interfere

with the performance and reliable operation of the pump. The

liquid’s temperature will rise due to friction and hydraulic losses

within the pump. Figure 2a illustrates the temperature rise in

relationship to the H-Q curve. The curve indicates that at or near

the best efficiency point,

the temperature rise is minimal and not significant to the pump

operation.

The process flow removes the generated heat from the pump. The

temperature increases as the flow through the pump is reduced.

Frictional and hydraulic losses generate heat, while the quantity

of fluid to which this heat is transmitted is reduced. The rise in

temperature results in the formation of vapor. The elevated

temperature / vapor pressure of the liquid results in problems

ranging from damaged seals and bearings to complete failure of the

rotating elements. Internal recirculation within the pump, often

termed incipient

recirculation, can cause a form of cavitation leading to impeller

damage. Internal recirculation is illustrated in Figures 2b and 2c.

High specific speed pumps have power curves which rise as the flow reduces. If adequate flow is not maintained, motor overload will result.

Continuous circulat ing system

Minimum requirement of continuous circulating system pump is

unrelated with the discharge of Process flow changes system. After

setting of minimum flow, through orifice plate directly backflow to

storage tank. Although continuous minimum flow circulation can

protect pump very good,but pump must provide greater power output

to ensure system process flow plus recycle flow, which causing

additional energy waste.

Control circulat ing system

Control circulatory system is assembly by the check valve, flow

gauge, minimum flow control valve, control circulation system,

control circulation system can provide minimum flow protection,

when process flow is greater than minimum flow of pump, loop

closed, no extra energy loss. But system is complex, control

components, purchase, installation, maintenance cost is higher.

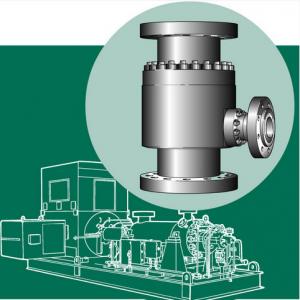

Automat ic recirculat ion control valve

Automatic recirculation valve set check valve, flow perception,

bypass control valve, multi-stage step-down in one, do not need

power, control system and wiring, essential safety. Taking up small

space, reducing the possibility of high-speed fluid to

malfunction to minimum, with lower Installation and maintenance

cost,It is the priority pump protection way of modern industrial

process.

ZDT Model Automatic recirculation control valve

ZDL Model Automatic recirculation control valve

ZDM Model Automatic recirculation control valve