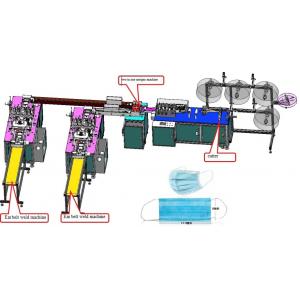

Face mask making machine / Medical nonwoven face mask production line

Add to Cart

Plate type medical face mask making machine

This medical face mask production line including one set of non woven face mask making machine and two sets of ear loop welding machines.

It belongs to a kind of flat face mask. The disposable three-layer face mask is made of two layers of non-woven fabric and filter paper. The disposable three-layer face mask is made of two layers of fiber non-woven fabric, which is used for medical and health care. In the middle, a layer of filter cloth with bacteria prevention up to 99% is added and welded by ultrasonic wave. The nose beam is made of environmental protection plastic strip, free of any metal, equipped with vapor permeable, comfortable and over passed. The filtering effect b.f.e is as high as 99%.

capacity:6000pcs/H.

Main feature:

1.automatic counter,can control production and process.

2.Variable frequency control can adjust the operation speed of the equipment according to the actual needs.

3.The equipment is highly automated, with low requirements for operating staff. It only needs to place and finish the finished products.

4.Modular and humanized design and maintenance convenience.

Process: after the whole roll of cloth is released, it is combined by the roller. The cloth is folded mechanically, pulled and released by the whole roll of nose strip. After cutting at a fixed length, it is imported into the wrapped cloth. The two sides are welded to the seal by ultrasonic welding, and then sealed laterally by ultrasonic, and then cut and formed by the cutter. The main body of the mask is divided into two ear belt spot welding machines by one drag two distribution machine, and the ear belt is welded by ultrasonic welding Set the number for stacking and receiving.

| no | Machines | description | QTY |

| 1 | cutter | Prevent roll ,complex film, mechanical fold, cut | 1 |

| 2 | two in one assigns machine | Interval shunt | 1 |

| 3 | ears belt weld machine | ears belt weld | 2 |

Equipment environmental requirements:

1. The ambient temperature is required to be between 15 ℃ and 35 ℃,

2. The humidity is required to be 40-80, without condensation,

3. Power supply grid requirements: AC220V, 50Hz;

4. Fluctuation of power supply grid: ± 5, and the grid ground wire meets the international requirements. Where the voltage amplitude is more than 5, automatic voltage stabilizing and current stabilizing devices shall be installed;

5. There shall be no strong electromagnetic signal interference near the installation equipment, and there shall be no radio transmitting station around the installation site(or relay station);

6. Foundation amplitude: less than 50um; vibration acceleration: less than 0.05g; avoid a large number of stamping and other machine tools nearby;

7. The equipment space shall be smoke-free and dust-free to avoid severe dust working environment such as metal polishing and grinding;

8. Air pressure: 86-106kpa;

9. Some environments should be equipped with anti-static floor, strengthen shielding, etc

Product material

| material | Melt blown fabric | Non-woven fabrics | Non-woven fabrics | Nose bar | Belt/band |

| picture | |||||

| Weight | 1800 roll/KGS | 1800 roll/KGS | 1200 roll/KGS | 5000 PC/KGS | 3300 PC/KGS |

| size | width:17.5 cm weight:20g | width:17.5 cm weight:20g | width:19.5 cm weight:25g | width:3 mm thickness:1mm length:95mm | width:2.5MM length:20CM |