Add to Cart

The saw blade welding tooth machine Induction heating equipment

Technical features

1. Automatic choose gear, feeding, wire feed welding process

2. Accurate, welding firm, stable quality

3. New gear selection system

4. Temperature to control to welding process can be fine-tuning and auto-tempering function, to adapt to a variety of special welding requirements

5. The whole process of computer control, which memory and query functions.

6. CNC control, safe and reliable

7. Advanced UHF heating controller, small size, low power consumption and high efficiency

8. Graphical user interface, clear concise, easy to grasp the operation of the program

9. Can be designed according to customers’ special requirements

Technical parameter

Saw blade OD | 80-500mm | Working power | 6KW |

Tooth face angle | -5°-+25° | Total power | 6.5KW |

Tooth length | 3.5-13mm | Working pressure | 6KG/cm² |

Tooth width | 1.5-6.5mm | Ventilated ability | >5m³.min |

Tooth thickness | 1.5-3.0mm | Cooling system power | 1.5KW |

Welding ability | 18t/min | Cooling water flow rate | 22L/Min |

Welding accurate | ≤0.05mm | Product size | 1200*960*1520mm |

Power supply | 220V 50HZ | Net weight | 323KG |

Operating Principle

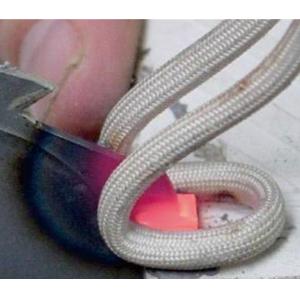

Frequency conversion electromagnetic induction heating or induction heating for short is a method for heating metal materials by converting power frequency power supply into that of specific range based on the principle of electromagnetic induction. It is mainly applicable to the metal hot working, heat treatment, welding and melting. This type of heating technique is also applicable to packing industry (such as sealing of aluminum foil used in medicine and food industry), semiconductor material (such as extruded monocrystalline silicon and heated affixing metal parts for auto glass).

Basic components of induction heating system include induction coil, AC power source and work pieces. Induction coil can be fabricated into different shapes as per different heated objects. The coil is connected with the power source providing alternating current for coil. The alternating current possessed by the coil can create a alternating magnetic field passing through the work pieces to produce eddy flow as required by heating.