Add to Cart

PE HDPE PPR Plastic Pipe Extrusion Line , PE Pipe Extrusion Machine

With CE Certificate

Brief introduction of pe pipe extrusion machine:

1.Production Flow of Pipe Production Line:

Material →Color Mixer →Automatic Feeder→Hopper Dryer →Single Screw

Extruder →Extrusion Mould & Calibrator → Vacuum Calibration Cooling

Tank → Spray Cooling Tank →Printer → Haul-off Unit →Cutter →Stacker

or Coiler

2.PE water supply pipe and gas pipe extrusion machine can produce

either PE water supply pipe or Gas pipe. It means that both PE

water supply pipe and PE gas pipe can be produced under the same

extrusion machine.

Description of pipe extrusion machine:

1.HDPE pipe extrusion line is used to produce pe pipe with diamater from 9 to 160 mm, which are effective,safe

Capacity: Conical single-screw extruder, suitable for process PE

with high capacity

Diameter: We have very successful production experience.Auxiliary

machine closely meet customer specifications. Nice apperance,

automatic control and stable running performance.

2.Specially-designed spiral moulds

for PPR pipes, with inside oil controlling temperature system.plastic machin,Extruder adopts big L/D and multi mixing structure, which is more suitable for the PPR low temperature extrusion production.with inside oil controlling temperature ,beautiful and practical stainless steel body for the vacuum calibration and spray cooling system, unique multi-section vacuum system ensures the stable sizing and cooling for pipes; special spray cooling system improves the cooling efficiency ;

3.Special water position, water temperature system make the machine more intelligent,Hauling-off unit adopts particular pedrail structure, which is easy and convenient for operation; pedrail clamping uses mechanical and pneumatic combining system, which is more reliable.Cutting system adopts saw blades and planetary cutting means; sumping uses hydraulic system , which ensures the smooth cross section; equipped with dust-collecting unit, which ensures the clean working environment.The unit is of reliable performance and high production efficiency .

Technical Specifications:

| Model number | 16/63 | 20/110 | 50/160 | 75/250 | 110/315 | 200/450 | 315/630 |

| Pipe diameter | 16-63mm | 20-110mm | 50-160mm | 75-250mm | 110-315mm | 200-450mm | 315-630mm |

| Max output | 150kg/h | 200kg/h | 350kg/h | 350kg/h | 350kg/h | 450kg/h | 850kg/h |

| Production rate | 1-15m/min | 1.2-12m/min | 0.6-8m/min | 0.5-4m/min | 0.4-3.7m/min | 0.3-3m/min | 0.2-2m/min |

| Extruder model | SJ-65/30 | SJ-65/33 | SJ-75/33 | SJ-75/33 | SJ-75/33 | SJ-90/33 | SJ-120/33 |

| Installed power | 85kw | 110kw | 125kw | 180kw | 260kw | 325kw | 480kw |

| Center height | 1000mm | 1000mm | 1000mm | 1000mm | 1100mm | 1100mm | 1200mm |

| Installation area | 35x3.0x2.0m | 38*3.1*2.2m | 38*3.1*2.2m | 40*3.2*2.4m | 42*3.2*2.4m | 52*3.3*2.6 m | 60*3.5*2.8m |

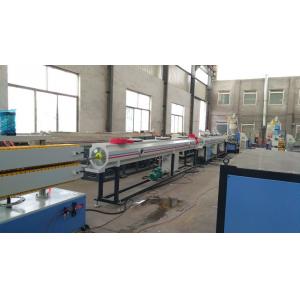

Machine display:

Tag: Plastic pipe making machine hdpe pipe extrusion machine pe pipe

production line